Alnico Pots

Our Alnico casting pots are designed to provide a significantly stronger holding force compared to Ferrite systems of a similar size. Unique in their capacity, these pot magnets are the only ones that can endure extreme temperature conditions. However, it’s important to note that the inclusion of Cobalt in these cast magnets does result in a higher cost. This makes them particularly suitable for specialized applications where temperatures range from +120°C to a maximum of 500°C.

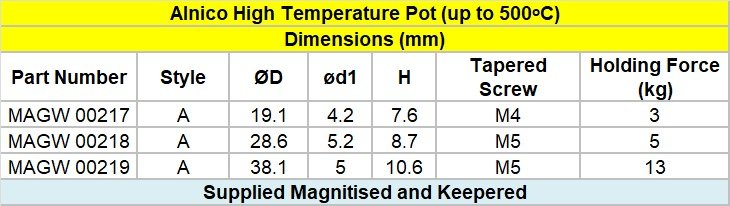

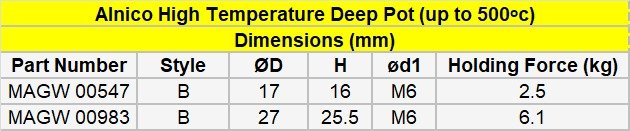

We offer two distinct designs in our Alnico pot magnet range:

Style A pots: These feature a shallow pot design, equipped with a countersunk hole on the active face. This design facilitates easy attachment using a countersunk screw, making it a versatile choice for various applications.

Style B pots: Characterized by their deep pot structure, these pots come with an internal thread on the non-active face. This feature allows for convenient and secure fastening, making them ideal for applications requiring a robust attachment method.

When utilizing our magnets, please consider the following key points regarding holding forces and screw selection:

Holding Forces: The holding forces we mention are calculated based on direct contact with a thick, clean mild steel surface. It is crucial to be aware that these forces may be reduced in scenarios involving heavily painted or corroded surfaces.

Screw Tightening: Care should be taken when tightening screws, as over-tightening can lead to cracking or other types of damage to the magnet.

Screw Selection: The choice of screws is vital. Standard steel screws can change the magnetic flux, leading to a decrease in the magnet’s overall strength. For optimal performance, we recommend using 304 stainless steel screws, which are less likely to interfere with the magnetic field.

Working Environment Consideration: It’s important to carefully evaluate the working environment in which the magnet will be used before deciding on the appropriate holding system. Factors like temperature, humidity, and exposure to chemicals can significantly impact the magnet’s performance and longevity.

View our other Magnet Materials and Products. Or, if you have any questions, email us at sales@magworks.us