Ferrite Pots

Sintered Ceramic Ferrite Magnets – Pot Magnets for Cost-Effective Performance

Our collection of sintered ceramic ferrite pot magnets offers a reliable and cost-effective solution for a variety of applications. While these magnets are generally larger and may not be suitable for space-constrained applications, they are designed for robust performance. The steel components are plated to enhance durability, and the ferrite is securely embedded to minimize corrosion risk. These pot magnets have a maximum operating temperature of +120°C.

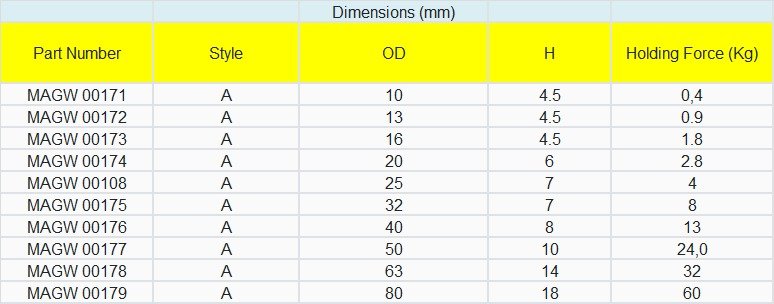

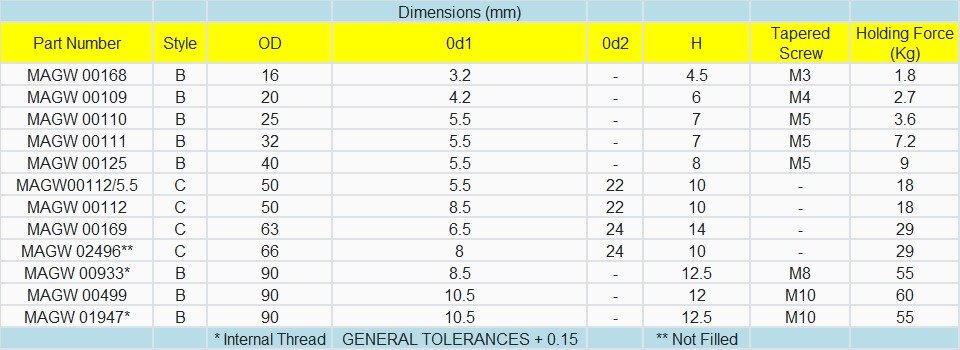

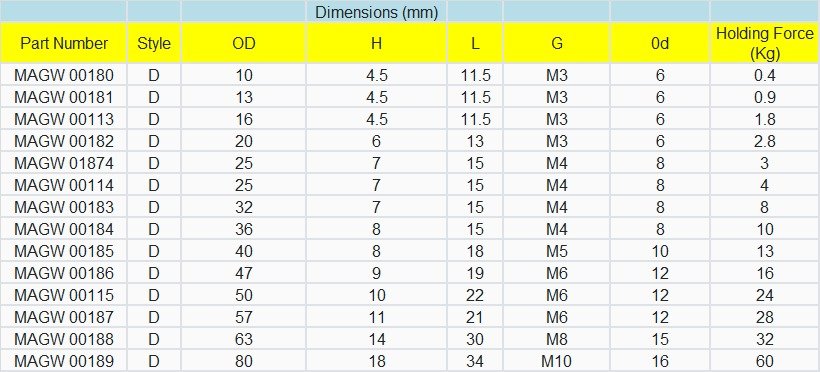

Our range includes four distinct styles:

Style A: This magnet features a straightforward design with the magnet encased within a steel cup. It’s ideal for applications where a simple, effective magnetic attachment is needed.

Style B: These pot magnets are equipped with a countersunk hole on the active face. This design allows for easy installation using a countersunk screw, making them versatile for a range of mounting scenarios.

Style C: Designed with a through hole mounting on the active face, these pot magnets enable secure positioning with a cap screw. This feature offers reliable installation in various applications.

Style D: This shallow pot magnet comes with an internally threaded stud, offering versatile installation options. For M4 threaded sizes, we also provide specially designed plated hooks, adding to the utility and functionality of these magnets.

Ferrite Pot with Steel Cap

Ferrite Pot with Centre Hole

Ferrite Pot with Female Thread

When selecting and using our pot magnets, please keep the following important information in mind:

Holding Forces: The specified holding forces are calculated based on the magnet’s direct contact with a thick, clean mild steel surface. Be aware that if the surface is heavily painted or corroded, the holding forces of the magnet may be reduced.

Screw Tightening: Caution is advised against over-tightening screws when installing these magnets. Over-tightening can cause cracking or other forms of damage to the magnet assembly.

Screw Selection: The choice of screw is significant. Using a steel screw can potentially alter the magnetic flux, resulting in a diminished magnetic force. For optimal performance, we suggest using 304 stainless steel screws when possible, as they are less likely to affect the magnet’s strength.

Assessment of Working Environment: Before finalizing your selection of a holding system, it’s important to consider the specific conditions of your application’s working environment. This includes factors like temperature, humidity, and exposure to chemicals, which can influence the magnet’s performance.

For more information about our Magnet Materials and Products, or if you have any specific inquiries, please don’t hesitate to email us at sales@magworks.us.

Ferrite Pots

Click to view