MAGNETISING

In-House Magnetizing Services with MSS – Utilizing High-Quality Capacitor Discharge Equipment

At MSS, a significant portion of our magnetizing processes takes place in-house, backed by substantial investments in cutting-edge capacitor discharge magnetizing equipment. This advanced machinery empowers us to achieve complete saturation of any magnetic material, and we possess the capability to demagnetize parts, facilitating inspections, cleaning, and overhauls.

Each type of magnetic material comes with a unique minimum magnetic field requirement for saturation and sustaining magnetism after the applied field is removed. For example, the easily magnetized cast Alcomax only requires a 0.3 Tesla field to become magnetic, whereas magnetizing Samarium Cobalt is more challenging, necessitating a 5 Tesla field.

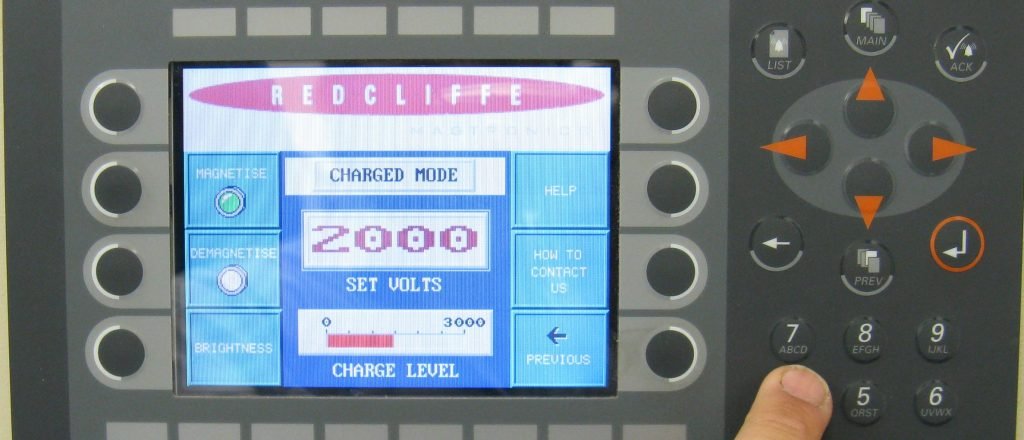

Our equipment operates by charging a large capacitor and swiftly releasing the stored charge through a copper-wound coil, generating a magnetic field. The strength of the field during magnetization depends on factors such as the energy released during capacitor discharge, the diameter of the copper coil, and the number of turns on the coil. Increased discharge energy, a smaller coil diameter (reducing air gap), and more coil turns collectively contribute to generating a stronger magnetic field.

MSS takes pride in a diverse range of capacitor discharge machines and copper coils, enabling us to tailor the magnetic field to the precise level required for a specific material’s size. Our equipment allows for adjustable output voltage ranging from zero up to 3000 V, resulting in a peak current of 35,000 A within the copper coil. This capability allows us to produce magnetic fields of up to 5.5 Tesla, ensuring successful magnetization even for the most challenging magnetic materials.