Miniature Machined Parts & Micro Precision Machining

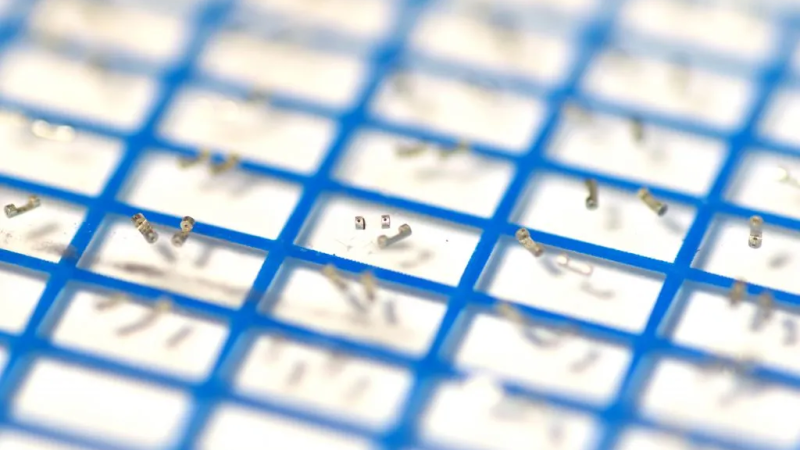

Micromachining enables the creation of intricate micro-components, essential in the medical and electronics industries. It involves ultra-precise tools and tight tolerances, with features often too small to be seen without magnification. This requires high-resolution inspection equipment to ensure exacting precision.

For projects requiring micro precision, we rely on the Tornos Swiss Nanos for machining miniature parts. These machines are specifically tailored for extremely small, high-precision workpieces. Equipped with 8 axes of motion and 2 independent tool systems, along with a flexible machining area, they are perfectly suited for a wide variety of micro workpieces where quality, precision, and efficiency are key.

For projects that demand even greater complexity, involving up to 12 axes of motion, we deploy our impressive fleet of 45 Tornos Deco CNC machines. This equipment excels in producing:

- Miniature Machined Parts

- Micro Gears

- Micro Shafts

- Micro Fittings

- Electronics

- Aerospace

- Automotive

- Medical

Certifications and Quality

- ISO 9001:2015 , AS-9100 & ISO 13485 certified quality environment

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA for automotive customers

- Industry 4.0 advanced quality system

- Fully compliant with the exacting requirements of our customers

- Skilled in KanBan and other customer driven quality and inventory management systems

- Proprietary 100% automated inspection available

Micro Machined Parts