Exploring Neodymium Iron Boron Magnets

If you operate in the manufacturing, engineering, or industrial sector, you likely utilize various types of magnets for your business equipment and operations. Neodymium iron boron (NdFeB) magnets have become a highly popular option over the last few decades due to their powerful magnetic properties. Read on to learn more about the composition, strengths, and industrial applications of neodymium magnets.

What Are Neodymium Magnets?

Neodymium magnets are a type of rare earth magnet made from an alloy of neodymium, iron, and boron. Neodymium, a rare earth mineral, is the key ingredient that gives these magnets their superior strength. The neodymium is combined with iron and boron using a specialized metallurgical process to create the NdFeB compound.

In comparison to traditional ceramic or ferrite magnets, neodymium magnets are 10-20 times stronger. Their magnetic power comes from the unpaired electrons within the neodymium interacting across magnetic domains. The other elements enhance the magnetic properties of the neodymium while also increasing heat resistance.

NdFeB magnets were first invented in the 1980s and commercialized by General Motors and Sumitomo Special Metals. They now rank as the strongest type of permanent magnet material known. Neodymium iron boron magnets offer a variety of advantages:

- Exceptionally strong magnetic fields

- High coercivity (resistance to demagnetization)

- High curie temperature (retention of magnetism at higher temperatures)

- Lightweight and compact in size

- Lower cost per magnetic flux output

These properties make neodymium magnets well-suited for a broad array of manufacturing and engineering uses. Their combination of high power and small size allows innovative designs and applications.

Grades of Neodymium Magnets

Not all neodymium magnets have the same composition and magnetic strength. NdFeB magnets are categorized into different grades based on their magnetic properties. The two main grade specifications are:

- Maximum Energy Product (BHmax) – This indicates how much magnetic energy the magnet can produce per unit volume. The higher the number, the stronger the magnetic field.

- Coercivity (Hcj) – This measures the magnet’s resistance to being demagnetized by an external field or temperature. Higher coercivity means better stability.

Common NdFeB magnet grades include:

- N35 – Low-cost magnets with BHmax of 10-12 MGOe and Hcj of 8-12 kOe. Used for basic holding and lifting.

- N42 – BHmax of 12-13 MGOe and Hcj of 10-12 kOe. Good value magnets suitable for motors and generators.

- N48 – BHmax of 14 MGOe, Hcj 12-14 kOe. High-performance magnets used in electric vehicles, wind turbines, etc.

- N50-N54 – Premium grades from 14-16 MGOe. Require dysprosium additions for maximum heat resistance. Used in precision equipment.

The grade choice depends on the intended operating conditions and strength needed for an application. Consider factors like temperature, external fields, costs, and safety requirements.

Shapes and Sizes

Neodymium magnets are very brittle and crack easily when machined or assembled. Thus, they are usually pre-formed into various sizes and shapes by the manufacturer. Common configurations include:

- Discs – Offer the greatest surface area for holding. Ideal for latches, fixtures, signs, etc.

- Blocks – Have a higher gripping force in a smaller area versus discs. Fit into tight spaces.

- Rings – Attach easily to cylinders and rods. Provide holding around a center.

- Squares – Allow better torque transfer and alignment versus discs. Work well in machines.

- Balls – No sharp edges or chipping. Used in bearings and joints.

- Segments – Flexible shapes for wrapping around curved surfaces. Create complete magnetic circuits.

- Custom shapes – Can be produced for unique applications and devices.

Sizes range from microscopic powders up to large blocks over 5 inches. Thicknesses are commonly available from 1/16” to several inches. Look for manufacturers that offer comprehensive dimensional options.

Coatings and Plating

While powerful, neodymium magnets have low corrosion resistance to humidity, rain, temperature swings, and acidic conditions. Exposed surfaces can oxidize, weakening their magnetic output.

To enhance environmental protection, neodymium magnets can be:

- Nickel-plated – Provides basic shielding in milder, indoor settings

- Zinc-plated – More heavy-duty rust protection for outdoor applications

- Epoxy-coated – Abrasion-resistant coating for wet, high-wear uses

- Rubber-coated – Soft cushion and electrical insulation for impact protection

- Gold-plated – Maximum chemical and moisture resistance for electronics

- Parylene-coated – Ultra-thin and clear treatment ideal for sensors

Proper coating allows neodymium magnets to withstand harsh operating environments while retaining their magnetic properties. It also makes them safer to handle and install without shattering.

Industrial Uses of Neodymium Magnets

Thanks to their unique advantages, neodymium iron boron magnets have become vital components across many manufacturing sectors:

Motors and Generators

NdFeB magnets enable high-efficiency electric motors and generators. Their strong magnetic torque and small volume fit into compact rotors. This enhances power output versus ferrite magnet motors. Lightweight neodymium magnets also reduce mechanical stress.

Magnetic Separation

Powerful neodymium magnets efficiently sort recyclable metals in waste streams at materials recovery facilities. Their magnetic fields separate iron and steel from aluminum, plastic, and glass.

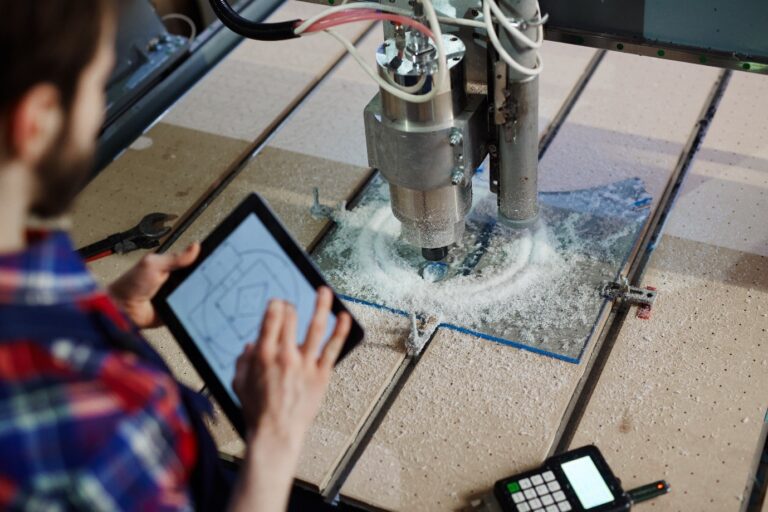

Magnetic Assemblies

NdFeB magnets securely hold doors, panels, and components together in a range of devices without contact or fasteners. This simplifies equipment assembly/disassembly for maintenance and cleaning.

Lifting and Handling

Compact neodymium magnets can securely grip and lift heavy metal objects like steel plates. Electromagnets made with NdFeB have high strength and low power draw.

Magnetic Sensors

The sensitivity of neodymium magnets enables miniaturized hall effect, reed switch, and other sensors. Their responsiveness and reliability supports precise position, speed, and current monitoring.

Loudspeakers and Headphones

Small neodymium magnets improve performance in speaker and headphone drivers. They create a strong, consistent magnetic field around voice coils for crisp sound. Lighter magnets also allow superior transient response.

Wind Power Generation

Large neodymium magnets maximize energy conversion in the turbines of wind power systems. Their power density withstands peak operating speeds and temperatures.

Electric Vehicles

NdFeB magnets enable high-efficiency traction motors for electric cars, bikes, buses, trains, etc. They optimize torque generation from the battery.

Medical Devices

Neodymium magnets operate actuators in ventilators, prosthetic devices, drug delivery systems, and surgical equipment where reliability is critical.

This wide range of applications highlights the versatility and performance benefits of neodymium iron boron magnets. Contact a top-tier global supplier to source the optimal NdFeB magnet configurations and grades for your manufacturing needs. With specialized engineering expertise and quality assurance, they can help you leverage neodymium magnets’ capabilities to improve your products. Investing in this advanced magnetic material will pay dividends through stronger, more energy-efficient equipment and systems.