Choosing a magnet assembly manufacturers in USA is an important decision. The right manufacturer can make your project successful by providing reliable products and meeting your specific needs. Magworks LLC is a trusted name in the industry, offering high-quality magnetic assemblies for various applications. To ensure you select the best partner, here are some key factors to consider.

Understanding Your Project Requirements

Start by knowing exactly what your project needs. Identify the type of magnet assembly required and its purpose. Are you working on a small custom design or a large production order? Being clear about your requirements will help you choose a manufacturer that can deliver the right solution.

Experience and Expertise Matter

Experience plays a big role in quality. A manufacturer with years of expertise understands the details involved in making magnetic assemblies. Magworks LLC has a proven history of delivering reliable solutions. Their knowledge helps prevent delays and ensures your project is handled professionally.

Customization Capabilities

Every project has unique needs, and not all manufacturers can provide custom solutions. Customization is crucial if your project requires specific designs, sizes, or magnetic strengths. Check if the manufacturer can adjust to your needs. We specialize in making custom magnet assemblies for various industries, ensuring your requirements are met accurately.

Quality Assurance and Certifications

Quality should never be compromised. Look for a manufacturer with strong quality checks and certifications like ISO. These certifications show that the company follows high standards. A focus on quality ensures that your products will work as expected.

Production Capacity and Lead Times

Time matters, especially if you have tight deadlines. Check if the manufacturer can handle the size of your order and deliver it on time. We use efficient processes to meet deadlines without affecting the quality of our products.

Technological Advancements

Modern technology leads to better results. Manufacturers that use advanced tools can deliver accurate and durable products. Techniques like CNC machining ensure precision, especially for complex designs. Partnering with a company that uses updated methods benefits your project in the long run.

Material Selection

The materials used in magnet assemblies affect their performance. Different projects require different types of magnets, such as neodymium, ferrite, or alnico. Choose a manufacturer who understands materials and can recommend the right one for your project.

Industry Knowledge and Support

A manufacturer with experience in your industry can add value to your project. Whether your project is in the aerospace, automotive, or medical fields, the company should understand the unique needs of your sector. Magworks LLC has worked with clients from various industries, offering the right guidance and solutions.

Cost-Effectiveness

Your budget is important, but quality should not be sacrificed. Compare prices from different manufacturers to find a balance between cost and reliability. We provide affordable options without lowering their high-quality standards.

Communication and Transparency

Clear communication is essential for smooth collaboration. Choose a manufacturer that updates you regularly and keeps the process transparent. From the first meeting to the final delivery, knowing what’s happening helps you stay confident in your project. Magworks LLC ensures open communication at every stage.

Commitment to Sustainability

Sustainability is becoming more important. Many companies now prefer working with manufacturers that follow eco-friendly practices. This includes reducing waste and using recyclable materials. By choosing a sustainable manufacturer, you can support a greener future.

Client Testimonials and Reviews

Reviews and testimonials help understand a manufacturer’s reputation. Positive feedback from clients shows that the company delivers on its promises. Look for case studies or ask for references to learn about their past work. Magworks LLC is known for its excellent service and customer satisfaction.

Future-Proof Solutions

Your manufacturer should be able to adapt to changes in your business. If you need to scale up production or adjust designs in the future, they should be ready to meet your evolving needs. We offer flexible solutions to support long-term success.

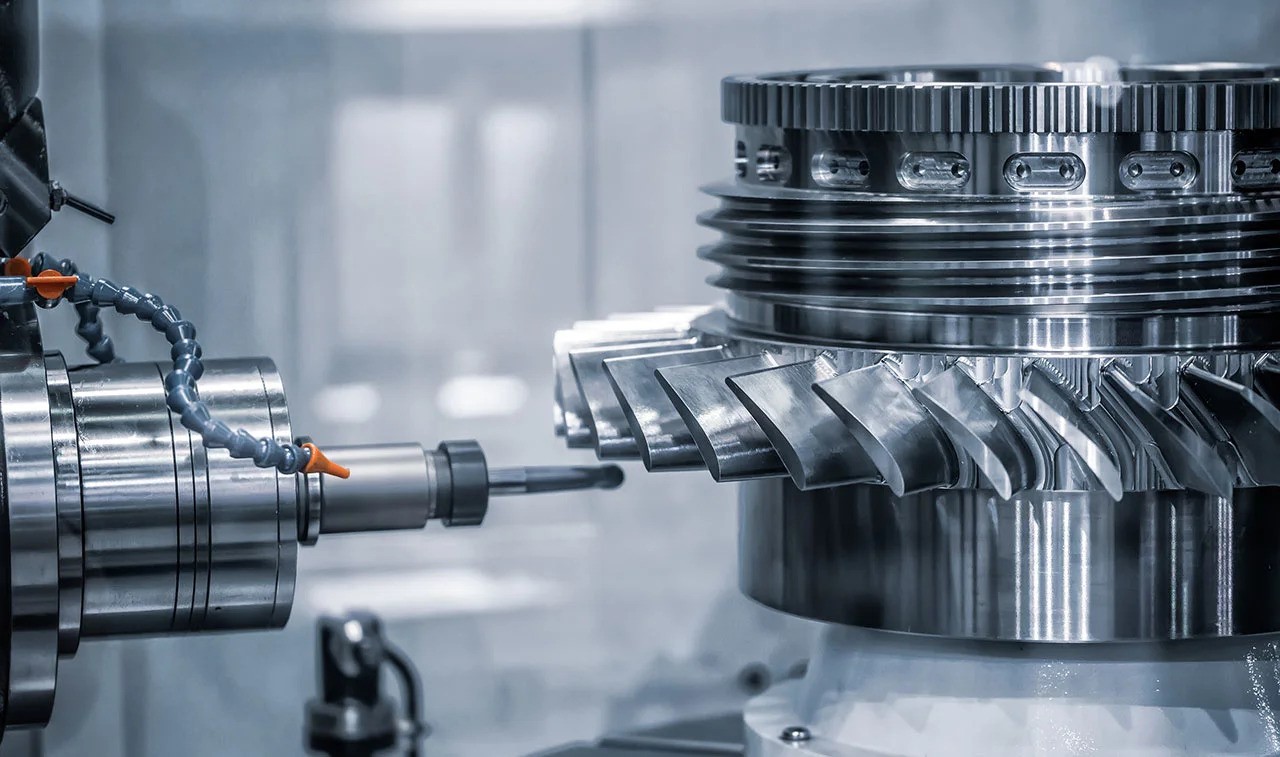

Integration with Advanced Machining

Magnetic assemblies often work with other components. Using advanced techniques, such as CNC machining, ensures these parts fit perfectly together. If your project involves industries like aerospace, having expertise in CNC aerospace machining is a big advantage. This helps in creating precise and reliable assemblies.

Final Verdict: Why Magworks LLC is Your Trusted Partner!

Choosing the right magnet assembly manufacturer in the USA can feel overwhelming, but Magworks LLC makes it simple. We combine experience, advanced technology, and a focus on customer needs to deliver top-quality solutions.

Our expertise extends to CNC aerospace machining, making them a dependable partner for projects requiring high precision. Whether you need magnetic assemblies for industrial use or specialized applications, Magworks LLC ensures your project’s success.

By working with a trusted company, you invest in quality and reliability. With Magworks LLC, you can confidently bring your ideas to life.