Modern automotive designs demand lightweight components and efficient performance. With this push for advanced solutions, Bonded NdFeb Magnets for Automotives have taken center stage. These magnets, known for their high performance and design flexibility, play a significant role in transforming automotive technologies. From electric vehicles (EVs) to advanced safety systems, these magnets are indispensable in today’s vehicles.

Below, we explore why these magnets are game-changers in the automotive industry and how they unlock efficiency without compromising performance.

What Are Bonded NdFeb Magnets?

Bonded NdFeb (neodymium-iron-boron) magnets are made by blending magnetic powders with resin or a polymer binding agent. Unlike sintered NdFeb magnets, which are typically solid and rigid, bonded NdFeb magnets are lighter and easier to shape. This flexibility allows for complex geometries that fit seamlessly into intricate designs.

For the automotive industry, this versatility makes them ideal for creating highly efficient motors, sensors, and other essential components.

Lightweight Materials for Modern Cars

Weight plays a critical role in vehicle design. Reduced weight directly improves fuel efficiency, performance, and even vehicle safety. Bonded NdFeb Magnets for Automotives provide a solution to achieve these goals without sacrificing functionality.

For example, these magnets are often used in small, energy-efficient electric motors. These motors can drive parts like power windows, automatic seats, and cooling fans while keeping overall vehicle weight lower. Lighter components mean less energy consumption, contributing to greener and more economical driving.

Where Bonded NdFeb Magnets Shine in Automotive Applications

Bonded NdFeb magnets are used across a wide range of vehicle systems. Here’s a closer look at some key applications:

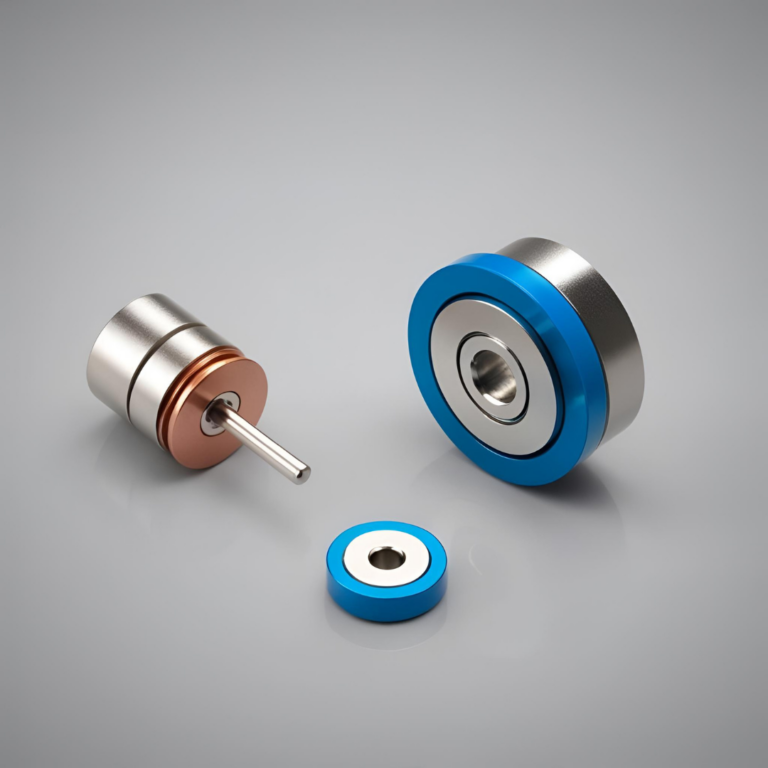

- Electric Motors in EVs

Electric vehicles rely heavily on efficient motors to ensure smooth operation. The unique properties of bonded NdFeb magnets make them perfect for powering the motors that drive these vehicles. They enhance torque and energy output while reducing size, leading to more compact motor designs.

- Advanced Sensors and Actuators

Cars today come loaded with sensors and actuators for features like automatic braking, adaptive cruise control, and parking assistance. Bonded NdFeb magnets help in the precise functioning of these systems by providing reliable magnetic fields that enable accurate detection and movement.

- High-Performance Alternators

Alternators convert mechanical energy into electrical power in vehicles. With bonded NdFeb magnets, these devices can work more efficiently by minimizing energy losses and generating more stable electrical output.

- Small Electric Components

Things like wipers, fuel pumps, and air conditioners rely on compact electric motors. By integrating bonded NdFeb magnets, these systems maintain performance while staying lightweight and efficient.

How Do These Magnets Contribute to Green Automotive Solutions?

Green technologies in the automotive sector aim to reduce pollution and dependence on nonrenewable energy sources. Electric cars are an excellent example of these efforts. Bonded NdFeb magnets align perfectly with green initiatives by providing components that use less material, produce less waste during manufacturing, and enhance overall vehicle efficiency.

These magnets also play an essential role in regenerative braking systems found in hybrid and electric cars. By helping capture and reuse energy lost during braking, they improve overall efficiency and range.

Manufacturing Advantages of Bonded NdFeb Magnets

Bonded NdFeb magnets aren’t just great for their applications—they also shine in their manufacturing advantages.

- Cost-Effective Production

Compared to traditional sintered magnets, bonded magnets are more economical to produce. Their production involves less raw material waste, saving costs while still offering high-quality performance.

- Design Customization

Because bonded NdFeb magnets can be shaped into unique forms, they easily meet the custom requirements of today’s automotive designs. Complex parts can be integrated seamlessly into advanced systems.

- Temperature Resistance

Automotive components often operate under high temperatures. Bonded NdFeb magnets are engineered to maintain their properties in these challenging environments, ensuring consistent performance even under stress.

Why Automakers Choose Bonded NdFeb Magnets

With all the benefits they bring, it’s no wonder automakers prioritize bonded NdFeb magnets. Their durability, efficiency, and lightweight properties make them a preferred choice over conventional materials. Automakers also value their ability to enhance performance while supporting sustainability initiatives—critical aspects in today’s market.

Whether in fuel-efficient gasoline cars or cutting-edge EVs, these magnets contribute to better designs that offer both driver comfort and cost savings.

A Peek Into the Future

As the automotive industry moves toward even more advanced technologies, bonded NdFeb magnets will likely become even more important. Innovations such as autonomous vehicles and next-generation EV batteries rely on components that deliver precision and durability. The flexibility of bonded NdFeb magnets means they can easily adapt to meet these demands.

Magworks LLC understands the evolving needs of the automotive industry and offers top-quality solutions with bonded NdFeb magnets. By working with us, automakers gain access to reliable components tailored to modern design requirements.

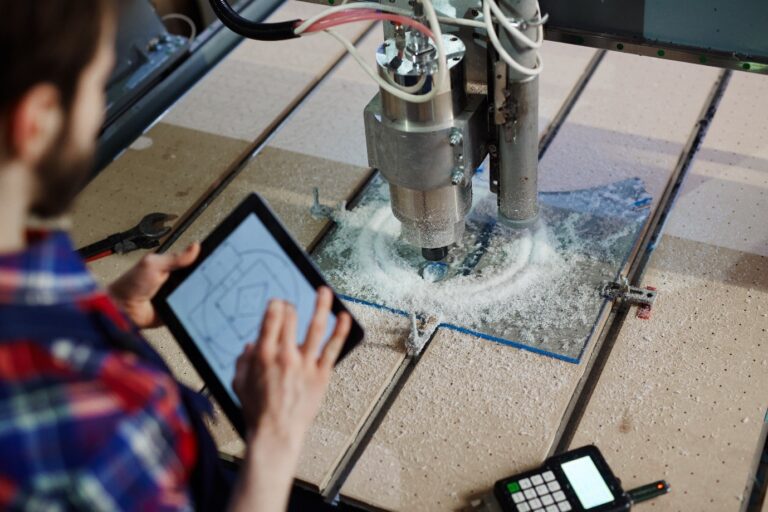

How Are Swiss Machine Parts Related?

While bonded NdFeb magnets address many aspects of efficiency in automotive, there’s more to designing a well-functioning vehicle. For example, precision parts like Swiss machine components are equally critical in building reliable systems. These highly accurate parts are commonly used in small assemblies that interact with magnets in sensors, motors, and other components.

By integrating bonded NdFeb magnets and Swiss machine parts, automakers can create efficient and lightweight solutions, ultimately enhancing the vehicle’s overall performance.

Wrapping It Up

The role of Bonded NdFeb Magnets for Automotives is central to lightweight and efficient designs in modern vehicles. Whether powering small electric motors or enhancing the reliability of advanced sensors, these magnets help manufacturers meet increasing demands for better performance and sustainability.

At Magworks LLC, we are committed to delivering high-quality bonded NdFeb magnets designed for automotive needs. Our expertise extends beyond magnets to supporting related solutions, including Swiss machine parts, ensuring a holistic approach to advanced automotive designs.

As the automotive industry continues to evolve, bonded NdFeb magnets will remain a key solution, driving efficiency and innovation across every type of vehicle.