In modern technology, precision and efficiency play a critical role in creating devices that are both reliable and energy-efficient. One component that stands out in this endeavor is the reed sensor magnet, a vital element in low-power sensing solutions. These small but powerful magnets are at the heart of numerous applications, helping to trigger reed switches and sensors in various industries. From everyday gadgets to complex machinery, reed sensor magnets have become indispensable, thanks to their simplicity and reliability. Let’s dive into what makes them so essential and how they work seamlessly with modern technologies.

What Are Reed Sensor Magnets?

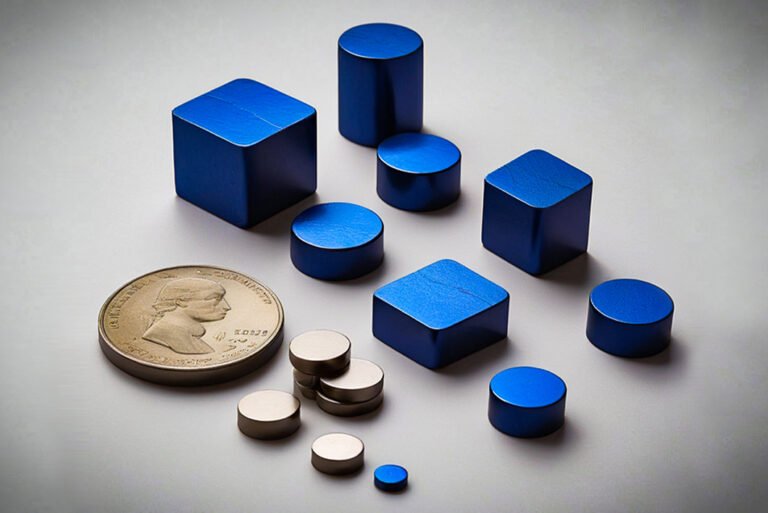

Reed sensor magnets are permanent magnets specifically designed to activate reed switches or sensors. These switches consist of thin, flexible metal reeds enclosed in a glass tube. When the magnet approaches, its magnetic field causes the reeds to move and make contact, completing the circuit. This action is what makes reed sensors an ideal solution for low-power applications—requiring no external power source to operate the switching mechanism.

Because reed sensors rely solely on magnets to function, they are highly efficient and incredibly reliable in harsh conditions. Their ability to operate without physical contact also reduces wear and tear, extending their lifespan. This makes them especially popular in applications where durability and precision are key.

Applications of Reed Sensor Magnets in Modern Systems

Reed sensor magnets have widespread uses across industries. Their versatility comes from their ability to be both highly accurate and extremely energy-efficient. Here’s a look at some practical applications:

- Consumer Electronics

Have you ever wondered how a phone cover automatically locks your screen? That’s thanks to reed sensor magnets. They are widely used in electronic devices like tablets and phones to detect movement or position. These sensors not only provide seamless functionality but also help conserve battery life.

- Automotive Industry

In vehicles, reed sensor magnets play a critical role in tasks like monitoring door positions and fluid levels. Their reliability under extreme conditions makes them indispensable in automotive systems where precision and safety are paramount.

- Industrial Automation

Industries heavily rely on automation to improve efficiency and productivity. Reed sensors, powered by magnets, are often used to detect position changes or count rotations in machinery. Their robust design ensures they function smoothly even in environments with high vibration or temperature fluctuations.

- Security Systems

Door and window alarms commonly use reed sensor magnets for intrusion detection. When a door or window is closed, the magnet and reed switch stay aligned. Opening the door disrupts the connection, triggering an alert. This simple yet effective mechanism enhances security in homes and businesses alike.

- Healthcare Devices

In medical equipment, reed sensor magnets contribute to functionality in devices like pacemakers, infusion pumps, and respiratory machines. These magnets ensure accurate operation and reduce energy consumption, which is vital for patient safety and device longevity.

Why Are Reed Sensor Magnets Ideal for Low-Power Sensing?

Reed sensors powered by magnets have distinct advantages over other sensing technologies, particularly in energy efficiency. Unlike optical or electronic sensors, they don’t require continuous power to monitor positions or changes. Here are some reasons why they are perfect for low-power sensing:

Minimal Power Consumption

Since reed sensors operate using only the magnetic field, they eliminate the need for additional power during standby. This significantly reduces energy use, which is particularly valuable in battery-operated devices.

Simple Design

The straightforward mechanism of reed switches—a magnet and two reeds—keeps their design simple yet highly effective. This also means fewer components are required, further enhancing energy efficiency.

Long-Lasting Performance

With no direct physical contact between moving parts, reed sensor magnets experience minimal wear and tear. This makes them durable and ensures long-lasting, reliable performance.

Advancing Innovations in Industry: A Closer Look at Magworks LLC

As technologies continue to evolve, Magworks LLC leads the charge in delivering advanced reed sensor magnets tailored to a variety of applications. With a commitment to quality and innovation, Magworks LLC’s products meet the needs of industries ranging from manufacturing to healthcare. By working with these precision-engineered magnets, businesses can ensure their devices remain energy-efficient, durable, and accurate in performance.

For industries such as semiconductor machining companies, which demand precise and reliable equipment, the integration of reed sensor magnets is a significant advantage. These components streamline complex tasks while minimizing energy use—a crucial factor in staying competitive.

Conclusion: Reed Sensor Magnets—Small but Essential for Big Solutions

Reed sensor magnets might seem like small components, but their impact on low-power sensing solutions is immense. From simplifying automation to enhancing energy efficiency, these magnets are paving the way for smarter and more sustainable technologies. Magworks LLC plays a vital role in this transformation, providing high-quality reed sensor magnets that cater to diverse industrial needs.

For businesses, including those in precision-heavy sectors like semiconductor machining companies, adopting advanced components such as reed sensor magnets opens up opportunities for greater efficiency and improved functionality. It’s clear that these unassuming yet powerful magnets are set to remain integral to the future of sensing solutions.