Manufacturing success often hinges on efficiency, accuracy, and the ability to produce parts that meet strict quality standards. If you’re looking for ways to enhance your operations, Swiss precision machining might hold the solution you need. Magworks LLC, a leader in manufacturing innovation, brings advanced techniques like Swiss precision machining to help businesses stay competitive in the market.

This blog explores how this method can transform your processes, ensuring both quality and reliability while reducing costs.

What is Swiss Precision Machining?

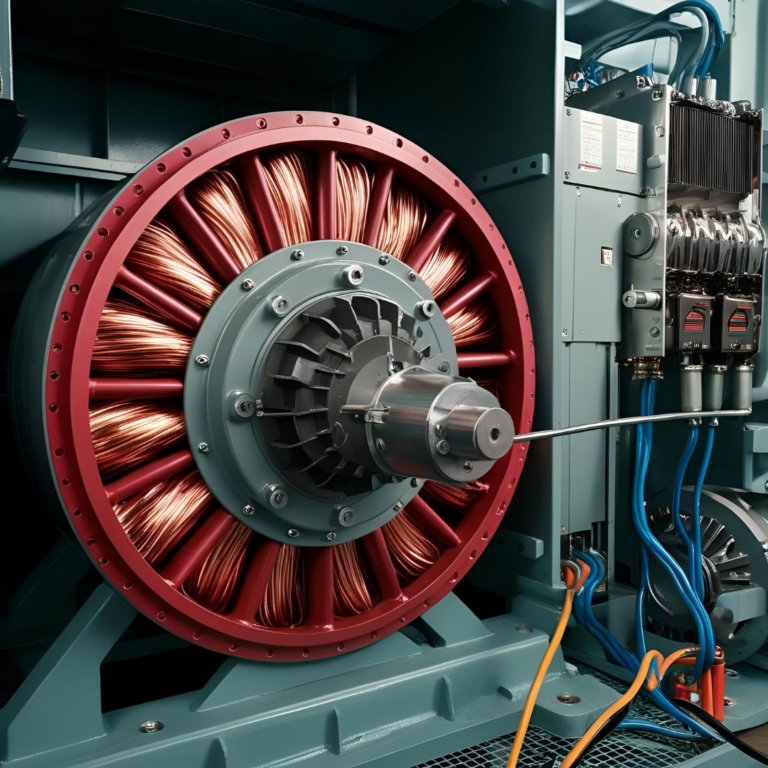

Swiss precision machining refers to a specialized manufacturing process where parts are machined with exceptional accuracy. Originally developed for creating high-quality watch components in Switzerland, this method uses specialized lathes capable of producing incredibly detailed pieces with tolerances as fine as a few microns.

Key to its success is the unique sliding-headstock lathe, which provides continuous material support during machining. This ensures each component maintains the exact specifications required, no matter how small or intricate.

Benefits of Swiss Precision Machining for Your Business

- Precision Beyond Comparison

For industries where accuracy isn’t just desirable but critical, Swiss precision machining delivers results that standard methods cannot match. Applications in aerospace, medical devices, and electronics demand components with tight tolerances, and this technology meets these expectations every time.

- Better Use of Materials

Swiss machining ensures minimal material waste. With resources being used more efficiently, your costs go down while still maintaining the high-quality output that your customers expect.

- Higher Productivity Levels

Swiss machines allow for the simultaneous operation of multiple tools on one part, reducing overall production time. This approach enables manufacturers to complete large production runs faster without compromising on quality.

- Wide Range of Applications

Swiss precision machining isn’t limited to one industry. Whether you manufacture medical components, small automotive parts, or precision electronics, this process fits the bill for various applications.

- Durability and Reliability

Components made through Swiss precision machining are often more durable and reliable due to the accuracy and consistency of the process. When every part meets stringent standards, the performance of the end product improves significantly.

Why Choose Magworks LLC?

Specialized Expertise

At Magworks LLC, we specialize in delivering solutions tailored to your manufacturing challenges. Our team’s experience in Swiss precision machining ensures that your parts are made to the highest standards.

Cutting-Edge Technology

We invest in state-of-the-art equipment to provide you with the latest advancements in precision machining. This commitment to innovation allows us to handle projects of any complexity, no matter the industry.

Customized Solutions

Every business has unique needs, and Magworks LLC works closely with you to develop solutions that align with your goals. From prototype development to large-scale production, we’re with you every step of the way.

Industries That Benefit from Swiss Precision Machining

- Medical Industry

In the medical field, precision is non-negotiable. Swiss precision machining is used to create essential items like surgical instruments, implants, and dental tools, all crafted to exact specifications. These components’ accuracy can mean the difference between success and failure in critical medical applications.

- Aerospace

When producing aerospace components, reliability is paramount. This process ensures that every part—from fasteners to intricate valve components—meets industry standards and can withstand demanding environments.

- Electronics

For smaller and more compact electronic devices, precision machining guarantees that all parts fit seamlessly. With Swiss machining, even the smallest circuit board components can be produced without error.

- Automotive

From fuel injectors to precision gears, automotive manufacturers rely on Swiss machining to create high-quality components that improve vehicle performance and reliability.

How Swiss Precision Machining Reduces Production Costs

Efficiency is one of the hallmarks of this process. Because Swiss machines handle multiple tasks in one setup, they minimize downtime and increase output speed. Additionally, less waste leads to material savings, while higher efficiency helps reduce labor costs. In the long term, Swiss precision machining not only improves product quality but also ensures better cost management.

Integrating Swiss Precision Machining into Your Operations

Are you wondering how to make the transition to Swiss machining? Here are the steps to get started:

- Evaluate Your Needs: Identify parts in your production line that require high precision or frequent improvements.

- Consult Experts: Work with professionals who understand Swiss machining’s capabilities. Magworks LLC offers consultations to determine how best to incorporate this technology into your workflow.

- Implement Gradually: Test the process with smaller production runs before scaling up. This approach allows you to fine-tune the setup to meet your specific requirements.

- Monitor Performance: Regularly check outputs for quality and efficiency to ensure the process meets your expectations.

Can Swiss Precision Machining Be Adapted for Smaller Runs?

The flexibility of Swiss machines makes them suitable for both small and large production runs. Whether you need one prototype or thousands of units, this method delivers consistent results. The adaptability is particularly beneficial for businesses aiming to test new product designs before committing to mass production.

The Role of Advanced Materials in Swiss Machining

Swiss precision machining can handle a broad range of materials, including metals, plastics, and composites. This versatility means it’s a top choice for businesses that work with cutting-edge materials. For instance, magnetic components such as strontium ferrite magnets can be integrated seamlessly into products thanks to this process’ precision.

Closing Thoughts

Swiss precision machining, offered by Magworks LLC, has the power to revolutionize your manufacturing process. Its ability to produce high-quality, precise parts ensures that industries like medical, automotive, and aerospace can meet their exacting standards. Moreover, it helps cut costs and save materials while boosting overall productivity.

For those working with advanced materials, such as strontium ferrite magnets, this process enables seamless incorporation into product designs. By choosing Swiss precision machining, you gain a reliable partner in modern manufacturing that keeps your business ahead of the curve. Connect with Magworks LLC today to learn how Swiss precision machining can help you achieve new levels of excellence!