Magworks specializes in custom aerospace machining, providing precision components for the aerospace and space exploration industries. With a focus on cutting-edge machining technologies, Magworks delivers high-quality parts that meet the most stringent industry standards.

Our innovative approach ensures increased efficiency and precision, helping to enhance the performance and reliability of aircraft and spacecraft components. By utilizing advanced techniques, Magworks is dedicated to supporting the growth and advancement of the aerospace sector through custom, high-performance solutions.

What is Custom Aerospace Machining?

Custom aerospace machining involves creating specific parts needed for aerospace applications. These parts must meet strict requirements to ensure they function perfectly under extreme conditions, such as high speeds, high temperatures, and low gravity. Machining these parts requires advanced technology and techniques to deliver parts with exceptional precision.

Common components created through custom aerospace machining include:

- Engine parts

- Structural components

- Landing gear

- Aircraft interiors

- Space mission components

Innovations in Custom Aerospace Machining: Increasing Precision

Today, we see some major advancements that make custom aerospace machining more efficient and precise.

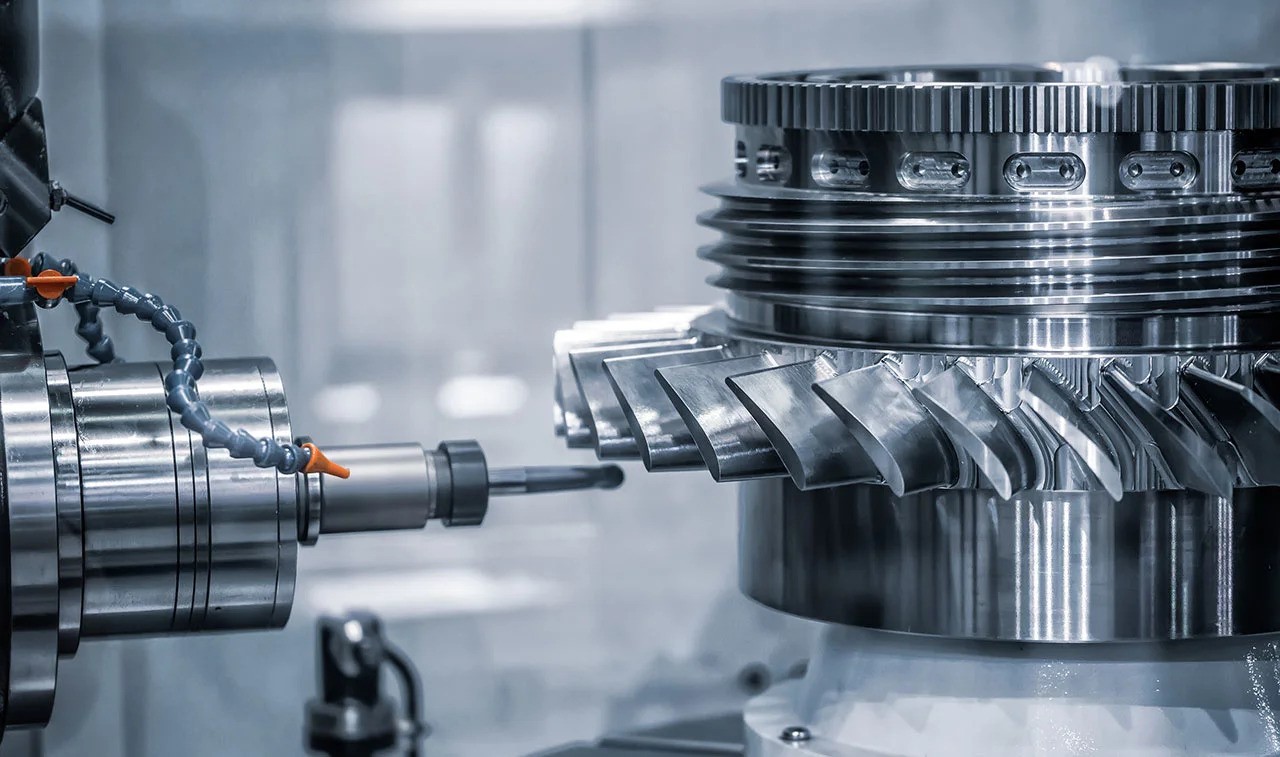

- Advanced CNC Machines

Computer Numerical Control (CNC) machines have transformed the aerospace industry by automating and controlling machining processes. This technology ensures consistent quality and faster turnaround times by allowing more intricate designs and reducing human error. Here’s how they improve precision:

- Tight tolerances: CNC machines can achieve tolerances in the micrometer range (fractions of a millimeter) for precise parts.

- Multiple axes: With multi-axis machining, manufacturers can produce complex shapes without needing to reposition parts manually.

- 3D Printing of Aerospace Parts

3D printing, also known as additive manufacturing, is rapidly becoming a game changer in the aerospace industry. It allows manufacturers to build parts layer by layer, resulting in reduced waste and quicker production.

- Customization: 3D printing enables the creation of highly customized parts for specific aerospace needs.

- Lightweight materials: Manufacturers are now able to print aerospace components using lightweight, durable materials, reducing the weight of the aircraft or spacecraft and improving fuel efficiency.

- Complex geometries: 3D printing allows the creation of intricate shapes that are otherwise difficult or impossible to machine with traditional methods.

- Cutting-Edge Material Innovation

Aerospace machining relies on the use of specialized materials, and recent advancements have led to better materials that can withstand even the most challenging environments.

- High-temperature alloys: Newer alloys are designed to maintain their strength and integrity under extreme temperatures, ideal for engine components.

- Titanium and composites: Lightweight materials like titanium and carbon fiber composites are not only stronger but also contribute to the overall fuel efficiency of aircraft.

- Ceramics: Ceramic composites are being developed to withstand high temperatures, such as those seen in aircraft engines or during space missions.

Efficient Manufacturing Techniques: Making Aerospace Machining Faster

While precision is key, the aerospace industry also demands efficiency in production. Advances in machining technology are allowing companies to create parts more quickly and at a lower cost, all while maintaining quality.

- Automation and Robotics

Automation plays a major role in reducing labor costs and increasing manufacturing speed. Robotics and automated systems streamline production by removing the potential for human error and reducing setup times.

- Faster throughput: Robotic systems enable faster cycles by continuously working without the need for breaks.

- Consistent quality: Automation ensures the same high standards across all parts, ensuring the reliability needed in aerospace applications.

- Lean Manufacturing and Waste Reduction

Lean manufacturing focuses on eliminating unnecessary steps in the manufacturing process to increase efficiency and cut waste. Using lean techniques, companies can streamline operations and deliver parts more efficiently.

- Reduced lead times: Streamlined processes mean that parts can be produced in less time.

- Lower costs: Less waste and improved organization cut material costs, offering savings to manufacturers and their customers.

- Advanced Inspection Systems

Having precise inspection tools is just as important as creating precise parts. Modern machines use advanced inspection techniques to verify every component after it’s created, ensuring the highest standards are met before the part is shipped.

- Non-destructive testing (NDT): Non-destructive methods such as ultrasonic testing and x-ray scanning ensure no flaws are present in critical components.

- Real-time data feedback: Advanced machines can send real-time data to operators, allowing them to make adjustments immediately if defects or issues arise.

Future Directions in Aerospace Machining

Aerospace is a fast-paced industry, with advancements constantly pushing the boundaries. The future looks bright for custom aerospace machining, with several technologies expected to drive growth.

- AI and Machine Learning

Artificial Intelligence (AI) and machine learning are likely to revolutionize aerospace machining. These technologies can analyze vast amounts of data, predict potential defects, and optimize machining processes automatically for even higher precision.

- Quantum Manufacturing

Quantum manufacturing, still in its early stages, holds great potential. By taking advantage of quantum computing and processing, manufacturers could unlock new methods for improving both precision and efficiency on a level we’ve never seen before.

- Autonomous Machinery

Similar to AI, the trend toward autonomy will lead to machines that can self-correct, learn from experience, and operate independently. This will allow for more flexible production systems and even quicker adaptation to customer requirements.

- Sustainability in Aerospace Machining

Environmental concerns continue to drive the development of new materials and processes in aerospace manufacturing. Green energy and sustainable practices are gaining importance, and companies are focusing on reducing waste, improving material recycling, and lowering energy consumption.

Custom Aerospace Machining and the Role of Electronic Components Manufacturers

It is important to note that electronic components play a crucial role in the functionality of custom aerospace machining. From advanced sensors to wiring used in aircraft and spacecraft, these electronic parts need to be as precise as the physical components they are connected to.

For instance, integrated circuits and sensor components must be designed and machined to extremely tight tolerances to ensure performance under the toughest conditions. As aerospace technology advances, the need for highly specialized electronic components grows. Many custom aerospace machining companies collaborate with trusted electronic components manufacturers to ensure both the mechanical and electrical parts meet exact specifications.

Final Verdict: Reach Out for Expert Manufacturing Solutions!

Briefly, custom aerospace machining is driving innovation in the aerospace sector, enabling new possibilities for aviation and space exploration. As technology advances, precision and efficiency continue to be prioritized. From advanced CNC machines to cutting-edge materials and 3D printing, the industry is always evolving to meet growing demands.

For high-quality, custom-machined components, don’t hesitate to connect with Magworks LLC. Email us at sales@magworks.us to start your project today! Our team is ready to work with you to create precision parts that meet your exact specifications.

Start Crafting the Future of Aerospace with Magworks Today!