At Magworks, we specialize in providing innovative solutions for the magnetic component industry, focusing on the production and supply of high-quality ferrite magnets. Widely used for their cost-effectiveness and magnetic stability, the performance of ferrite magnets is significantly influenced by factors such as temperature.

Understanding the ferrite magnet temperature range and its impact on function is crucial. Magworks offers expert insight to help engineers and manufacturers optimize the use of ferrite magnets, ensuring maximum performance and efficiency across diverse applications.

Let’s break down the essential details about how temperature affects ferrite magnets and what you need to know to optimize their use.

What are Ferrite Magnets?

Ferrite magnets are ceramic compounds typically made from a mix of iron oxide and metallic elements like barium or strontium. These magnets are popular for their:

- Cost-effectiveness: An affordable alternative to other high-performance magnets.

- High resistance to demagnetization: Perfect for a variety of applications like motors, speakers, sensors, and magnetic closures.

- Durability: Well-suited for environments where the budget is a priority, but performance still matters.

Temperature Sensitivity: Why it Matters

Temperature changes can significantly impact ferrite magnets. While these magnets are more stable than many soft magnetic materials, they aren’t immune to the effects of extreme temperatures. Here’s a look at how different temperatures influence their properties:

- High Temperatures:

- Irreversible Loss of Magnetization: Exposure to high temperatures leads to irreversible magnetization loss, causing a permanent reduction in magnetic strength.

- Reduction in Coercivity: Above 250°C, ferrite magnets lose their ability to resist becoming demagnetized, weakening their magnetic field.

- Curie Temperature: At around 450°C (850°F), ferrite magnets completely lose their ferromagnetic properties and cease to function as magnets.

- Low Temperatures:

- Magnetic Retention: Ferrite magnets tend to retain their magnetic strength in cold temperatures.

- Decreased Flux Absorption: At extremely low temperatures, ferrite magnets’ ability to absorb and store magnetic flux weakens, impacting efficiency.

- Performance Decline: While the magnets don’t lose their magnetism, sub-zero temperatures can reduce system efficiency, resulting in slower operation and energy inefficiencies.

The Temperature Range: Stay Within Limits for Peak Performance

To ensure that ferrite magnets operate at their best, it’s crucial to stay within the manufacturer’s recommended temperature range. For most standard ferrite magnets:

- Optimal Temperature Range: Between -40°C to 250°C. This range ensures both mechanical durability and maximum magnetic strength.

- Avoiding Extreme Heat: Exposure to temperatures above 250°C can cause permanent damage, including a drop in magnetization strength and potential structural breakdown at the Curie point (450°C).

- Managing Cold Environments: Low temperatures can lead to reduced efficiency but will not typically demagnetize ferrite magnets. However, their reduced ability to store flux may affect device performance.

How to Maintain Stability in Varying Temperatures?

- Temperature Control: Ensuring the environment remains within the optimal range is key to preserving the performance of ferrite magnets.

- Specialized Materials: For critical applications, consider selecting ferrite magnets designed for wider operating ranges or adding coatings or treatments to mitigate temperature risks.

- Design Considerations: For industries that face fluctuating temperatures, like electronics or automotive, it’s essential to design systems that account for thermal management to optimize the magnets’ lifespan.

Considerations for Electronics and Automotive Sectors

Ferrite magnets are vital in industries such as electronics and automotive manufacturing. These sectors face unique challenges in temperature management:

- Electronics: Maintaining stable performance across temperature fluctuations is key. Power stability must be carefully monitored to ensure device longevity.

- Automotive: Automotive systems such as motors, sensors, and ignition systems must endure continuous temperature changes. Understanding the ferrite magnet temperature range ensures these parts remain reliable throughout their operational life.

The Role of Ferrite Magnets in High-Precision Applications

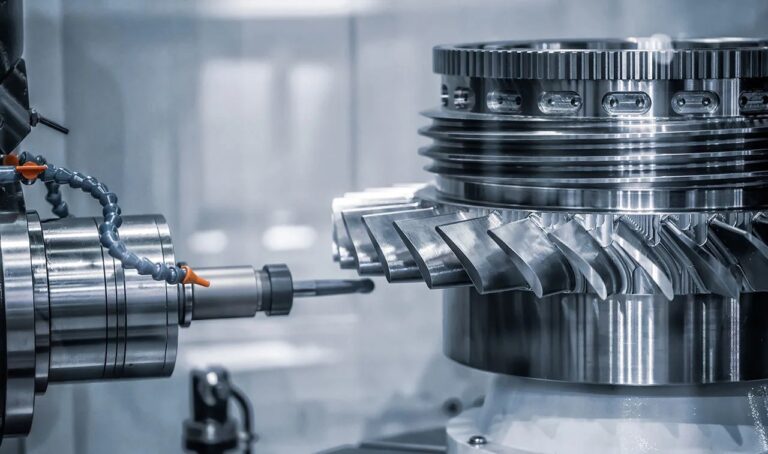

In advanced manufacturing processes like wafer lamination, ferrite magnets must work seamlessly alongside other technologies. Temperature fluctuations can impact both the magnet’s performance and the lamination process, so it’s important to manage the heat to preserve the magnet’s stability and functionality.

The Bottom Line: Keeping Ferrite Magnets in Top Condition with Magworks LLC

Understanding the ferrite magnet temperature range is essential to maintaining the best performance across a wide variety of uses. High temperatures can lead to irreversible magnetic loss, while cold temperatures might cause inefficiencies in operation. Manufacturers need to be mindful of these limits to avoid potential failures.

At Magworks LLC, we specialize in providing high-quality ferrite magnets tailored to your specific application needs. From industries relying on automotive innovation to the expanding world of electronics, we can help you find the perfect magnet solution.

Don’t let temperature extremes limit your equipment’s potential! We are committed to supporting you with ferrite magnet products that stand up to various environmental conditions.

Ring us today to find out more about our superior ferrite magnet options and how they can help optimize your applications across different temperature ranges!