The aerospace industry demands perfection. From commercial jets to military aircraft, every component must be manufactured with extreme precision to ensure safety, performance, and reliability. At MagWorks LLC, we specialize in aerospace machining, delivering high-precision components that meet the industry’s strictest quality standards.

If you’re searching for aerospace machining near you, we provide advanced CNC machining solutions tailored for the unique challenges of aerospace engineering. With decades of experience, cutting-edge technology, and a commitment to excellence, we ensure that every part we produce meets the highest levels of accuracy and durability.

The Importance of Precision in Aerospace Machining

Aerospace components operate under extreme conditions, including high speeds, intense heat, and heavy mechanical stress. Even the slightest error in machining can lead to catastrophic failures. That’s why aerospace manufacturers require:

- Ultra-precise tolerances – Ensuring components fit perfectly and function flawlessly.

- High-strength materials – Using materials like titanium, stainless steel, and exotic alloys that can withstand extreme environments.

- Stringent quality control – Meeting industry certifications such as ISO 9001:2015, AS-9100, and DFARS compliance.

At MagWorks LLC, our aerospace machining services are designed to meet these exact requirements. We combine cutting-edge CNC machining techniques with rigorous inspection processes to deliver components that exceed expectations.

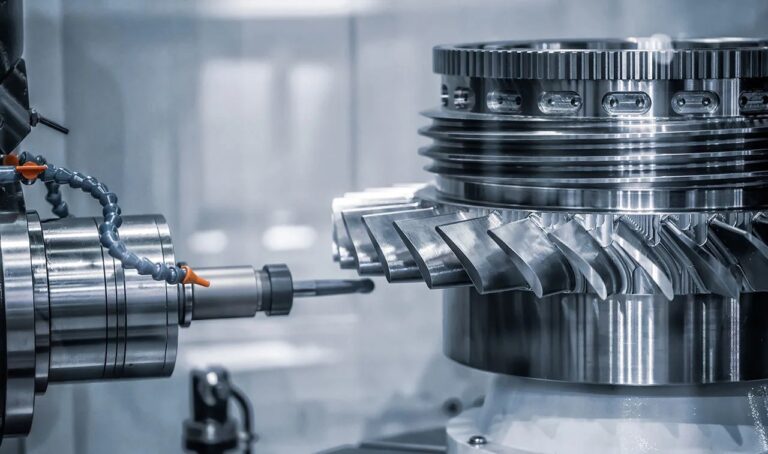

Advanced Aerospace Machining Capabilities

To meet the ever-evolving demands of the aerospace industry, we utilize a range of advanced machining techniques that provide unmatched accuracy and efficiency.

CNC Swiss Machining for Intricate Aerospace Components

Swiss machining is ideal for producing small, complex components with high precision. Whether it’s fuel nozzles, sensors, or aircraft fasteners, our CNC Swiss machining technology ensures superior quality and consistency.

Multi-Spindle Cam Automatics for High-Volume Production

For large-scale production of aerospace parts, our multi-spindle cam automatic machines provide fast, repeatable, and accurate machining. This allows us to deliver high-quality components while maintaining cost efficiency.

CNC Turning and Milling with Up to 12-Axis Precision

Our 12-axis CNC machining centers allow us to create highly detailed geometries, making them perfect for crafting complex aircraft components such as turbine blades, landing gear parts, and structural assemblies.

Esprit CAD/CAM System for Seamless Design-to-Production

We leverage the Esprit CAD/CAM system to develop and machine intricate aerospace parts with precision. This advanced software enables us to create complex designs while maintaining strict tolerances and reducing production time.

Why Material Selection Matters in Aerospace Machining

Aerospace components must withstand extreme conditions, which is why material selection is crucial. At MagWorks LLC, we work with high-performance materials that offer:

- High strength-to-weight ratio – Essential for lightweight aircraft components.

- Corrosion and heat resistance – To withstand harsh environments.

- Superior durability – Ensuring long-term reliability and safety.

We machine components from materials such as:

✔ Titanium – Used in aircraft structures and engine parts due to its strength and heat resistance.

✔ Stainless Steel – Ideal for high-stress applications in aircraft frames and landing gear.

✔ Exotic Alloys – Including Inconel and Hastelloy for extreme temperature applications.

✔ High-Temperature Plastics – For electrical insulation and lightweight aerospace components.

All materials used in our aerospace machining processes meet DFARS compliance, ensuring superior quality and traceability.

Industry Certifications and Compliance Standards

Quality assurance is a priority at MagWorks LLC. We adhere to strict industry certifications to guarantee precision and safety in every component we produce. Our certifications include:

✅ ISO 9001:2015 – Ensuring consistent quality in aerospace manufacturing.

✅ AS-9100 Certification – Meeting the aerospace industry’s specific quality standards.

✅ ISO 13485 Certification – Precision machining for aerospace medical applications.

✅ DFARS Compliance – Ensuring materials meet U.S. Department of Defense requirements.

These certifications ensure that our aerospace clients receive flawless, high-performance parts that meet all regulatory and safety requirements.

Why Choose MagWorks LLC for Aerospace Machining?

If you’re looking for aerospace machining near you, MagWorks LLC is a trusted name in precision engineering. We stand out due to our:

- Decades of experience in aerospace component manufacturing.

- Cutting-edge CNC machining technology for unmatched precision.

- Strict quality control processes to meet the industry’s highest standards.

- Global reach with manufacturing capabilities in the USA, UAE, and UK.

- Custom solutions tailored to meet unique aerospace design requirements.

Final Thoughts: Elevating Aerospace Manufacturing with MagWorks LLC

Precision and reliability are non-negotiable in the aerospace industry. Whether you need turbine components, aircraft fasteners, or mission-critical aerospace parts, MagWorks LLC delivers exceptional aerospace machining solutions to meet your needs.

With our state-of-the-art CNC machining capabilities, industry certifications, and a commitment to quality, we ensure that every component we produce meets the highest standards.

Looking for aerospace machining near you? Trust MagWorks LLC for precision-crafted aerospace components that keep the world flying safely.