Neodymium iron boron (NdFeB) magnets are among the strongest permanent magnets available today. Their incredible strength, compact size, and durability make them essential for countless applications. However, not all neodymium magnets are the same—different shapes serve different purposes. Whether you need strong magnetic discs for electronics or custom-shaped magnets for industrial applications, choosing the right shape is key to maximizing performance.

At MagWorks LLC, we specialize in providing neodymium iron boron magnets for sale, offering various shapes to meet the needs of different industries. Here’s a breakdown of common shapes and their specific uses.

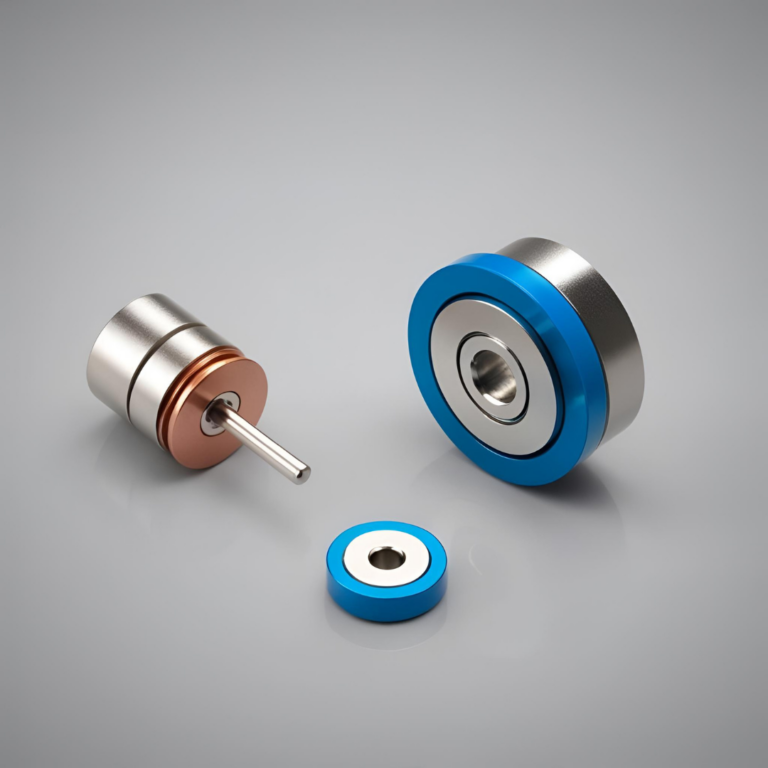

1. Disc Magnets – Ideal for Compact, High-Strength Applications

Strong magnetic discs are one of the most commonly used neodymium magnets. Their round, flat shape allows for easy integration into various devices, making them popular in consumer electronics, medical devices, and industrial tools.

Common Applications:

- Speakers & Audio Equipment: Provide high-quality sound output by generating powerful magnetic fields.

- Medical Devices: Used in MRI machines and portable medical sensors.

- Automotive Sensors: Help detect motion, positioning, and speed.

- DIY & Hobbyist Projects: Often used in crafts, home projects, and magnetic closures.

Why choose disc magnets? Their ability to generate strong magnetic fields while maintaining a small footprint makes them ideal for space-limited applications.

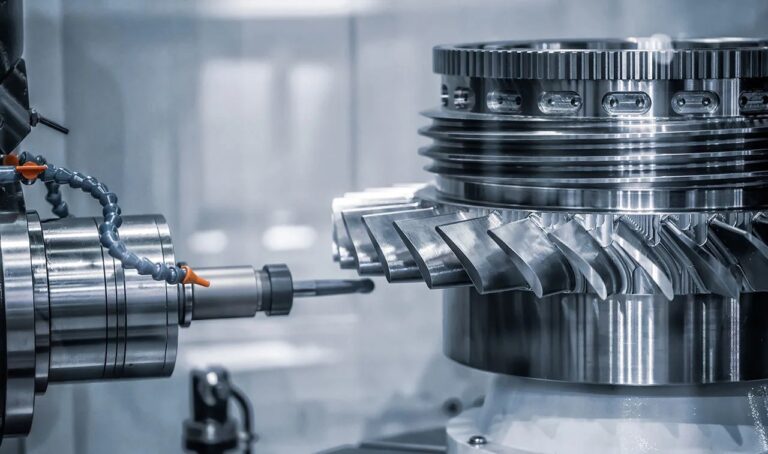

2. Block Magnets – Power and Stability in Industrial Applications

Block magnets, also known as rectangular or square magnets, offer a larger contact surface, making them excellent for applications requiring strong holding force and stability.

Common Applications:

- Magnetic Clamping & Workholding: Used in CNC machining and metal fabrication.

- Magnetic Latches & Closures: Found in cabinet doors, toolboxes, and industrial storage.

- Wind Turbines & Generators: Help convert mechanical energy into electrical power.

- Transportation & Aerospace: Used in electric vehicle motors and aircraft systems.

Why choose block magnets? Their strong pull force and stability make them perfect for heavy-duty applications.

3. Ring Magnets – The Perfect Choice for Rotational Applications

Ring magnets have a hole in the center, allowing them to be easily mounted onto shafts, screws, or other cylindrical objects. These magnets are widely used in motors, sensors, and filtration systems.

Common Applications:

- Electric Motors & Generators: Key components in high-performance brushless motors.

- Magnetic Couplings: Allow for contactless torque transfer in pumps and mechanical systems.

- Automotive Sensors: Used in ABS braking systems and other vehicle safety mechanisms.

- Water Filtration Systems: Help remove ferrous particles from liquids.

Why choose ring magnets? Their ability to generate strong magnetic fields while allowing rotational motion makes them essential in engineering and mechanical applications.

4. Ball Magnets – Small But Mighty for Unique Applications

Neodymium ball magnets are tiny but powerful. They are often used in precision applications where uniform magnetic fields are needed.

Common Applications:

- Magnetic Therapy & Healthcare: Used in magnetic bead bracelets and other wellness products.

- Scientific Research & Experiments: Help demonstrate magnetic field behaviors.

- Magnetic Fasteners: Used in jewelry clasps and secure closures.

Why choose ball magnets? Their spherical shape allows for flexible movement and multidirectional magnetic fields.

5. Arc & Segment Magnets – Essential for High-Performance Motors

Arc and segment magnets are specially designed for electric motors, particularly in aerospace, automotive, and industrial applications. They create an optimized magnetic field to improve motor efficiency and performance.

Common Applications:

- Brushless DC Motors (BLDC): Essential for drones, electric vehicles, and industrial machines.

- Turbine & Generator Systems: Help generate and regulate electricity.

- Defense & Aerospace Equipment: Used in high-speed aircraft and military-grade machinery.

Why choose arc magnets? Their curved shape allows for seamless integration into circular systems, maximizing efficiency.

Choosing the Right Neodymium Magnet for Your Application

When selecting a neodymium magnet, it’s important to consider factors like shape, size, strength, and temperature resistance. Whether you need neodymium iron boron magnets for sale for an engineering project or high-strength strong magnetic discs for an industrial application, MagWorks LLC has you covered.

At MagWorks LLC, we specialize in custom neodymium iron boron magnets designed to meet the highest industry standards. Our magnets are trusted across medical, aerospace, automotive, and industrial sectors. Contact us today to find the perfect magnet solution for your needs!