A BRIEF HISTORY OF MAGNETS

The history of magnets and their discoveries is a fascinating journey through scientific progress:

Ancient Greece: The use of naturally occurring iron ore called magnetite was first documented by the ancient Greeks. They used magnetite in the creation of the mariner’s compass. Magnetite was later referred to as “lode-stone,” with “lode” meaning to lead.

1600: William Gilbert made a groundbreaking discovery when he realized that the Earth itself behaves like a giant magnet.

1785: Charles Coulomb made a significant contribution by discovering the square law of attraction and repulsion between electrical charges and magnetic poles.

1820: Hans Christian Oersted’s discovery was a pivotal moment in the history of electromagnetism. He found that an electrical current could deflect magnetic needles, demonstrating the link between electricity and magnetism.

1830: Michael Faraday made a groundbreaking discovery when he found electromagnetic induction, laying the foundation for the development of electric generators.

1865: The invention of the dynamo marked the beginning of the era of electricity, revolutionizing various industries.

1873: James Clerk Maxwell published his equations, which unified the theories of Gauss, Ampere, and Faraday, providing a comprehensive understanding of the relationship between electricity and magnetism.

1921: The introduction of Cobalt and Chrome steels expanded the range of magnetic materials available.

1935: The development of Alnico, an alloy of Aluminum, Nickel, and Cobalt, provided powerful magnets with unique properties.

1950: Philips introduced the first non-metallic magnets known as Ferrites, which found applications in various electronic devices.

1970: Stronger magnets, specifically Samarium Cobalt magnets, were developed, earning them the name “Rare Earth magnets.”

1983: Neodymium Iron Boron magnets were patented by Japanese researchers, offering exceptional magnetic properties.

2000: The 21st century has seen rapid advances in Neodymium magnets, with ongoing developments focused on improving performance and corrosion resistance.

These milestones in magnetism have shaped our modern world, enabling innovations in technology, navigation, and various industries.

MAGNET MATERIALS

Choosing the right magnet material and grade is crucial for your specific application. Here are the main families of magnet materials to consider:

Alnico: Alnico magnets are known for their excellent temperature stability and strong magnetic properties. They are often used in applications where high temperatures are a concern.

Ferrite: Ferrite magnets, also known as ceramic magnets, are cost-effective and have good resistance to corrosion. They are widely used in various applications due to their affordability.

Samarium Cobalt (SmCo): SmCo magnets are known for their high magnetic strength and temperature resistance. They are ideal for applications where a strong magnetic field is required at elevated temperatures.

Neodymium-Iron-Boron (NdFeB): NdFeB magnets are the most powerful permanent magnets available. They offer exceptional strength in a compact size, making them suitable for a wide range of applications.

Our website provides a selection of standard magnet sizes that are typically in stock or available on short notice. However, we recommend seeking our advice to ensure you choose the right magnet for your specific job. If you don’t find the size you need on our website, please don’t hesitate to contact us, as we can often supply other sizes quickly.

HEALTH AND SAFETY

Safety is paramount when handling magnets. Here are important safety rules to follow:

Pacemakers and Data: Magnets can affect pacemakers and damage magnetically stored data. Keep magnets away from pacemakers and sensitive electronic devices.

Mechanical Forces: Modern permanent magnets can attract steel or other magnets with significant mechanical force. Be cautious of injuries, as large magnets can act over wide distances.

Handling Brittle Magnets: Most sintered magnets are hard and brittle. If they snap together, they may shatter into sharp-edged pieces. Always wear safety glasses when handling them.

Sensitive Instruments: Strong magnetic fields can influence or damage sensitive electronic or mechanical test instruments. Keep magnets at a safe distance from such devices.

Explosive Environments: Never handle magnets in areas with explosive gas. Moving or snapping magnets, especially rare-earth magnets, may cause sparking.

Machining and Grinding: When machining or grinding magnets, they may spontaneously combust due to fine dust. Rare-earth magnets are pyrophoric and oxidize rapidly. Use coolants and proper precautions.

Additionally:

Radiation Exposure: Avoid exposing permanent magnets to strong radiation over extended periods, as it can affect their magnetic properties.

Temperature Limits: Be aware of the maximum temperature a magnet can withstand, as high temperatures can decrease its magnetic properties.

Neodymium Magnet Care: Neodymium magnets are susceptible to corrosion. Keep them away from hydrogen or saltwater environments and store them in a dry place to prevent surface oxidation.

Always prioritize safety when working with magnets to prevent accidents and damage.

INFLUENCE ON HUMAN BEINGS

There are typically no harmful effects when touching magnets. However, it’s worth noting that only very strong magnetic fields, with flux densities of 1 Tesla or higher, and prolonged exposure to such fields may potentially lead to biological changes. There are some reports suggesting beneficial effects at lower and medium flux densities, although scientific opinions on this matter are divided.

It’s also important to mention that individuals who are allergic to ceramics or specific materials may have similar reactions when in contact with magnet materials, whether magnetized or not. In unique cases, it’s advisable to inquire for further details.

WHAT IS A PERMANENT MAGNET?

A permanent magnet refers to a material that, when subjected to a strong magnetic field, starts to generate its own magnetic field and continues to do so even when the initial field is no longer present. This self-generated magnetic field remains constant without weakening, as long as the material is not exposed to environmental changes or external magnetic field alterations. The capacity to maintain its magnetic field unchanged is a key characteristic that determines the types of applications where a permanent magnet is suitable. Typically, only specific alloys possess the ability to become permanent magnets.

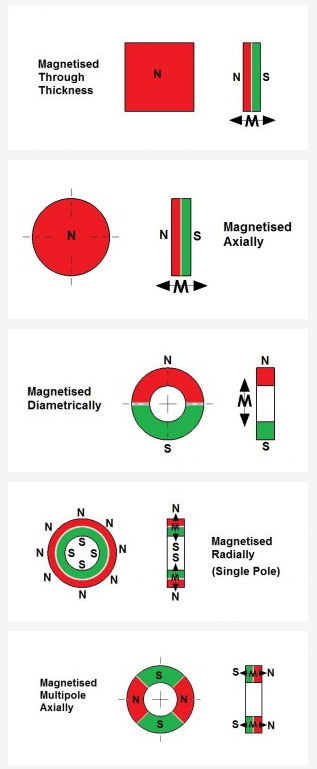

DIRECTIONS OF MAGNETISM