No products in the cart. Add Products

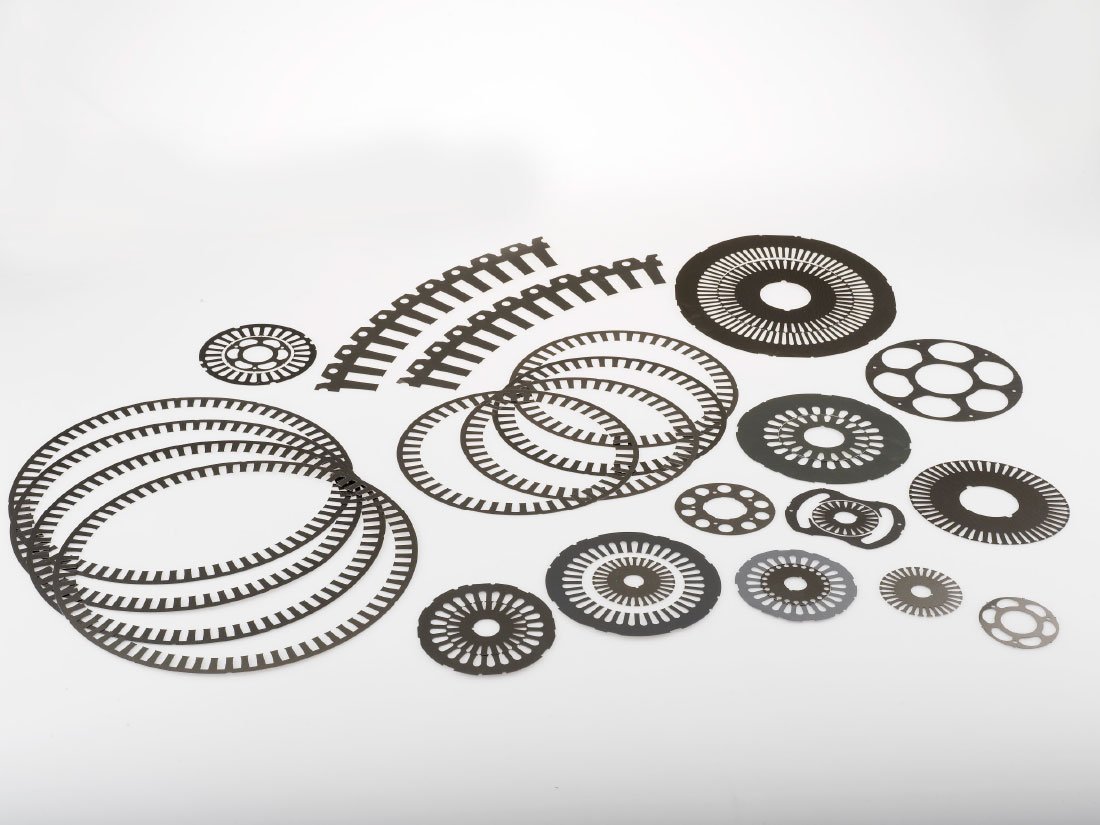

Laminated Wafer

Magworks LLC specializes in the progressive stamping of motor laminations, ranging from 12.5 mm OD to 380 mm OD. The company employs a variety of materials, including fully processed silicon, cobalt (Hiperco 50 and VACODUR 49), and nickel alloys, with thicknesses ranging from 0.1 mm to 0.8 mm.

In addition to stamping, Magworks LLC manufactures end laminations for insulation purposes, using a diverse range of materials. The company boasts a comprehensive Assembly Department capable of producing fully finished laminated stator and rotor stacks, ready for customer winding or direct assembly into the final product. These stacks can be supplied in straight or skewed configurations, with processes such as stacking, bonding, staking, riveting, welding, fluidizing (epoxy insulation), grinding, and honing.

Magworks LLC offers the flexibility to provide stacks of any diameter or height, whether as prototypes, short-run lots, or large quantity production. The Toolroom department supports the assembly process by designing and constructing all necessary stacking fixtures and special tooling, ensuring compliance with customer specifications, including unique skew angles.

The Grinding Department at Magworks LLC is well-equipped with machines capable of ID and OD grinding, jig grinding, and honing. The company guarantees ID and OD tolerances to ± 0.025 mm, and OD to ID concentricity held to 0.025 mm, even for delicate and “flexible” stacks with thin wall sections. State-of-the-art inspection equipment is utilized to verify concentricity and roundness with an accuracy of 0.75 µm.

Magworks LLC has optimized grinding wheels, coolants, and procedures to minimize grinding smear, ensuring the best magnetic properties of the assembly. This commitment to precision and quality extends to every aspect of the manufacturing process, making Magworks LLC a reliable partner for motor lamination solutions.

Contact Us

We are happy to receive new inquiries for standard or non-standard magnetic products and assemblies.

Please feel free to contact us with your requirements, giving as much information as you can and attaching drawings wherever possible