You’re drawn to magnets, right? Those shiny metals seem to defy gravity with their invisible powers of attraction and repulsion. Well, get ready to have your mind magnetized as we dive into the different types of magnetic materials that make compasses point north and keep your favorite photos stuck to the fridge. In this infographic, you’ll discover the science behind magnetism and get up close and personal with the atomic makeup of various magnetic metals, alloys, and composites. From the common refrigerator magnets made of flexible rubber bonded with ferrite powder to the rare earth neodymium magnets powering MRI machines, you’ll become an expert on all things magnetic. So charge up your brain and get ready to have some attractive fun! This infographic will stick with you.

What Are Magnetic Materials?

Magnetic materials are objects that can be magnetized or that are naturally attracted to magnetic fields. Several types of magnetic materials exist, including ferromagnetic, paramagnetic, and diamagnetic materials.

Ferromagnetic Materials

Ferromagnetic materials, like iron, nickel, and cobalt, have strong magnetic properties and are highly responsive to magnetic fields. They can be permanently magnetized and are used to make permanent magnets. Ferromagnets have a strong attraction to magnetic fields and are used in technologies like hard drives, magnetic resonance imaging (MRI) machines, and Maglev trains.

Paramagnetic Materials

Paramagnetic materials, such as aluminum and platinum, are weakly attracted to magnetic fields. They don’t retain magnetization when the external field is removed. Paramagnets have a small positive magnetic susceptibility and are often used as an alloying element to enhance the magnetic properties of ferromagnetic materials.

Diamagnetic Materials

Diamagnetic materials, like copper, silver, and gold, are very weakly repelled by magnetic fields. They have a small negative magnetic susceptibility. When placed in a magnetic field, diamagnetic materials create an induced magnetic field in the opposite direction. Diamagnetic materials are used in technologies like superconducting magnets to provide stability.

While ferromagnetic materials are the most commonly known magnetic materials, paramagnetic and diamagnetic materials also have important applications. By understanding the properties of different magnetic materials, scientists and engineers can develop new technologies to harness their potential.

The strength and behavior of magnetic materials depends on factors like temperature, magnetic field strength, and material composition. By manipulating these properties, we can tune magnetic materials for specific applications. The discovery of new magnetic materials and effects remains an active area of research in physics and materials science.

Classification of Magnetic Materials

Magnetic materials can be organized into several categories based on their magnetic properties. The three most common types are ferromagnetic, paramagnetic, and diamagnetic materials.

Ferromagnetic Materials

Ferromagnetic materials, like iron, nickel, and cobalt, have strong magnetic properties and are attracted to magnetic fields. These materials contain magnetic domains that are aligned in the same direction. As the material is exposed to a magnetic field, these domains line up, causing the material to become magnetized. Even after the external field is removed, ferromagnetic materials remain magnetized. Common examples of ferromagnetic materials include refrigerator magnets, magnetic recording tapes, and most permanent magnets.

Paramagnetic Materials

Paramagnetic materials, such as aluminum and platinum, are weakly attracted to magnetic fields. They contain atoms with unpaired electrons that act like tiny magnets. When exposed to a magnetic field, these tiny magnets align slightly with the field. However, their alignment is random in the absence of an external field. Paramagnetic materials have magnetic permeability slightly greater than one and magnetic susceptibility less than 0.1. Examples include liquid oxygen and manganese sulfate.

Diamagnetic Materials

Diamagnetic materials, such as gold, silver, and copper, are repelled by magnetic fields. They contain atoms with no unpaired electrons. When exposed to a magnetic field, the electrons in the atoms realign slightly, which creates small magnetic fields opposite to the external field. This causes the material to be pushed away from the magnetic field. Diamagnetic materials have magnetic permeability slightly less than one and negative magnetic susceptibility. Bismuth and graphite are common examples of diamagnetic materials.

By understanding the different types of magnetic materials, you can determine which ones suit your needs. Whether you want a material strongly attracted to magnets or one that repels them, there’s a magnetic material for any application.

Ferromagnetic Materials

Ferromagnetic materials are strongly magnetic materials that create their own persistent magnetic fields. The term ferromagnetic comes from ferrous, meaning iron, because iron is one of the most common ferromagnetic elements. Ferromagnetic materials contain magnetic domains that align in the same direction when exposed to an external magnetic field. Even when the external field is removed, ferromagnetic materials retain some degree of magnetization due to the aligned electron spins in their domains.

Common ferromagnetic materials include iron, nickel, cobalt and some of their alloys such as steel. These materials are used to make permanent magnets as well as components like transformer cores.

Iron

Iron is one of the most well-known ferromagnetic materials. In its pure form, iron maintains its ferromagnetism up to 1,393°F. Iron’s high saturation magnetization, a measure of the degree of magnetization that can be achieved, allows it to produce very strong magnetic fields. However, its high coercivity, which is the strength of the external magnetic field required to change the magnetization, and moderate electrical resistance limit some of its applications.

Steel

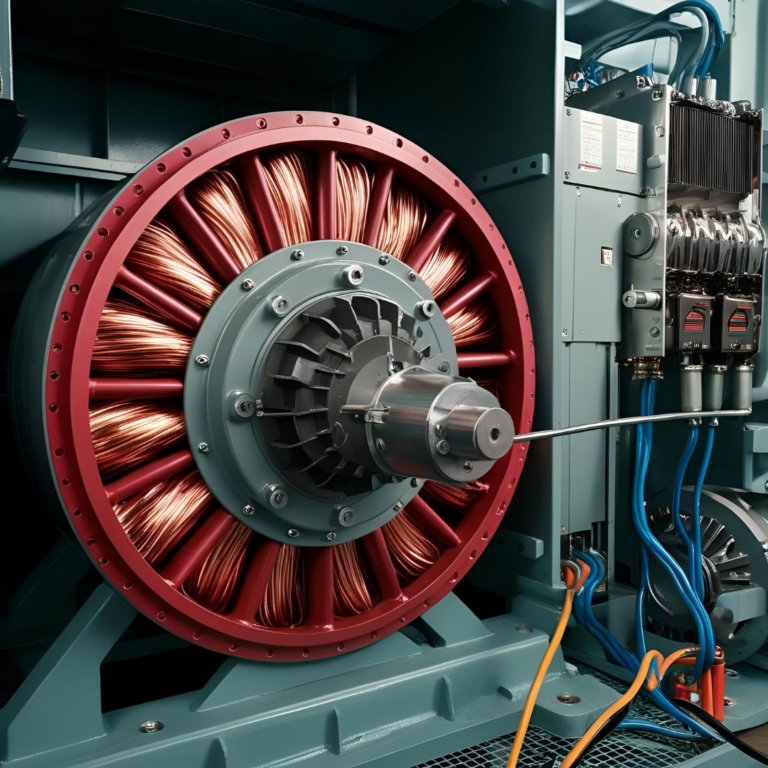

Steel is an alloy of iron and carbon that exhibits ferromagnetic properties. By controlling the amount of carbon, steel can be made with a range of coercivities and electrical resistances suitable for different applications. Many electrical devices like motors, generators, and transformers contain steel cores and components. Certain grades of steel, such as 416 stainless steel, have high resistances to corrosion and are used for applications like magnetic assemblies in harsh environments.

Nickel

Nickel is another common ferromagnetic material with a Curie point of 627°F, which is the temperature above which its ferromagnetism disappears. Nickel has a lower saturation magnetization than iron but higher coercivity and electrical resistance. These properties make nickel well-suited for applications where stronger permanent magnets and higher heat tolerances are required, such as in motors, sensors, and memory storage devices.

In summary, ferromagnetic materials contain magnetic domains that can be aligned to produce strong magnetic fields. Their properties like high saturation magnetization, coercivity, and electrical resistance determine their suitability for various applications that rely on magnetism. With the range of ferromagnetic materials available, there are many options to choose from based on your specific needs.

Diamagnetic Materials

Diamagnetic materials are weakly repelled by magnetic fields. Their electrons orbit in pairs and cancel each other out, so the material itself has no net spin or magnetic moment. When an external magnetic field is applied, it causes the electrons to shift slightly, creating small magnetic fields that oppose the external field. This results in a weak repulsion.

Examples of Diamagnetic Materials

Some common diamagnetic materials include water, wood, copper, silver, and gold. Diamagnetic properties are present in all materials, but are usually very weak. Interestingly, living tissues are also diamagnetic because of their high water content. This is what allows magnetic resonance imaging (MRI) to work. The strong magnetic fields used in MRI cause the water molecules in the body’s tissues to become slightly magnetized in the opposite direction.

Applications

The diamagnetic effect is usually too weak to have many practical applications on its own. However, it can be enhanced by cooling materials to very low temperatures. When this is done, some materials become superconducting – meaning they lose all electrical resistance. These superconducting materials can then be used to create extremely powerful magnets for applications like magnetic resonance imaging (MRI), nuclear magnetic resonance (NMR) spectroscopy, and particle accelerators.

Some potential future applications of enhanced diamagnetism include quantum computing, fusion power, and more sensitive detectors. Diamagnetic materials may also eventually be used to create optical magnets and cloaking devices.

While diamagnetic materials themselves are not strongly magnetic, their properties are crucial for enabling many important technologies. By understanding how these materials interact with and repel magnetic fields, scientists and engineers have found ways to harness them for amazing and important applications.

Paramagnetic Materials

These materials have atoms with unpaired electrons that give them a slight magnetic moment. The small magnetic fields of the unpaired electrons align in the presence of an external magnetic field, causing paramagnetic materials to become magnetic. However, their magnetism disappears once the external field is removed.

What are Paramagnetic Materials?

Paramagnetic materials have a weak attraction to magnetic fields. They don’t retain magnetization when the external field is removed. Examples of paramagnetic materials include aluminum, platinum, manganese, and liquid oxygen. These materials contain unpaired electrons that spin in the same direction when exposed to a magnetic field.

How Paramagnetism Works

In paramagnetic materials, the unpaired electrons in each atom spin in random directions when there is no external magnetic field. But when exposed to a magnetic field, the spins of the unpaired electrons align in the same direction and add together to produce a weak magnetic moment. The material becomes slightly magnetic, but loses this magnetization once the magnetic field is removed as the electron spins again become randomly oriented.

Properties of Paramagnetic Materials

Paramagnetic materials have the following properties:

- They become magnetized when exposed to a magnetic field but quickly lose magnetization when the field is removed.

- They have a small positive magnetic susceptibility meaning they are weakly attracted to magnetic fields.

- Their magnetization is linearly proportional to the applied magnetic field.

- They have randomly oriented magnetic moments in the absence of an applied field due to the presence of unpaired electrons.

Some paramagnetic materials have technological applications, such as platinum which is used in magnetic resonance imaging (MRI) scanners. Understanding the properties of these materials helps in developing new technologies that utilize magnetic fields.

The key to remember with paramagnetic materials is that their magnetism is temporary and induced by an external magnetic field. Once the field is gone, so too is their magnetic personality.

Magnetic Raw Materials

The materials that are naturally magnetic or can be magnetized fall into several categories. The most well-known are metals like iron, nickel, and cobalt. These ferromagnetic metals contain magnetic domains that are aligned even without an external magnetic field.

Iron

As the most abundant magnetic metal, iron is critical for many commercial applications. Pure iron is rarely used, though, since iron alloys like steel contain iron and have enhanced properties. Steel, an iron alloy containing up to 2% carbon, is a staple of the construction industry due to its strength and durability.

Nickel

Nickel is an important additive to increase the corrosion resistance of alloys. Stainless steel, for example, contains at least 10% nickel which gives it excellent rust-resistance for use in cutlery, appliances, and architecture. Nickel is also a key component of several strongly magnetic alloys like Alnico.

Cobalt

Cobalt is used to produce high-performance permanent magnets when alloyed with other metals like aluminum, nickel, and copper. Alnico, an aluminum-nickel-cobalt alloy, produces magnets that can withstand high temperatures without significant loss of magnetic strength. Samarium cobalt magnets contain rare earth elements like samarium and provide the strongest permanent magnets commercially available.

Other magnetic metals include gadolinium and dysprosium, which are rare earth elements used in high-tech applications like computer hard drives, wind turbines, and electric vehicles.

Various metal alloys can also be magnetized to different degrees depending on their composition and manufacturing process. By understanding the properties of these raw materials, scientists have developed permanent magnets and electromagnets that power many of the technologies we now rely on in our daily lives. The future will likely bring further magnetic innovations through the discovery and development of new magnetic materials.

FAQ on Magnetic Materials

As you explore the world of magnets, you’re bound to have some questions about magnetic materials. Here are some of the most frequently asked questions and their answers.

What are the most common types of magnetic materials? The three main categories of magnetic materials are ferromagnetic, paramagnetic, and diamagnetic. Ferromagnetic materials, like iron, nickel, cobalt, and some of their alloys, are strongly attracted to magnetic fields. Paramagnetic materials, such as aluminum and platinum, are weakly attracted to magnetic fields. Diamagnetic materials, like copper, silver, and gold, are weakly repelled by magnetic fields.

What is the difference between a permanent magnet and an electromagnet?

Permanent magnets produce their own magnetic field constantly. They are made of ferromagnetic materials like iron, nickel and cobalt that have strong magnetic properties. Electromagnets produce a magnetic field only when an electric current is applied. They are made by winding coils of wire around a ferromagnetic material like iron. The magnetic field disappears when the current is turned off.

How are magnets used in everyday life? Magnets are used in many devices we use every day. Speakers, microphones, and headphones use magnets to produce and sense magnetic fields which represent sound. Magnets are used in motors that power many appliances like refrigerators, washing machines, and fans. Credit cards and hard drives use magnetic strips and coatings to store data. Magnets are even used in certain medical devices, like MRI scanners.

What determines how strong a magnet is? Several factors determine how strong a magnet is:

- The type of material it’s made of: Ferromagnetic materials, especially alloys with iron, cobalt or nickel, produce the strongest magnets. •The number of magnetic domains: More domains pointing in the same direction create a stronger field. •Size and shape: A larger magnet has a stronger field than a smaller one of the same material and orientation. Some shapes, like spheres, maximize the number of domains.

•Orientation of magnetic moments: When more moments are aligned in the same direction, the field is stronger. •Presence of an electric current: For electromagnets, a higher current means a stronger magnetic field.

Conclusion

So there you have it, folks – a rundown of the main types of magnetic materials to give you a primer. From ferromagnetic metals to paramagnetic salts, you now know some of the key properties and uses that set each category apart. Whether it’s generating electricity, storing data, or picking up pins, different magnetic materials make our modern world possible. And magnets themselves are still a source of fascination – just think back to playing with them as a kid. If this has sparked your interest to learn more, dive deeper into the science and see where it takes you. The magnetic forces of the universe have so much more to reveal.