Magnets in Motors & Generators: Key Role & Types

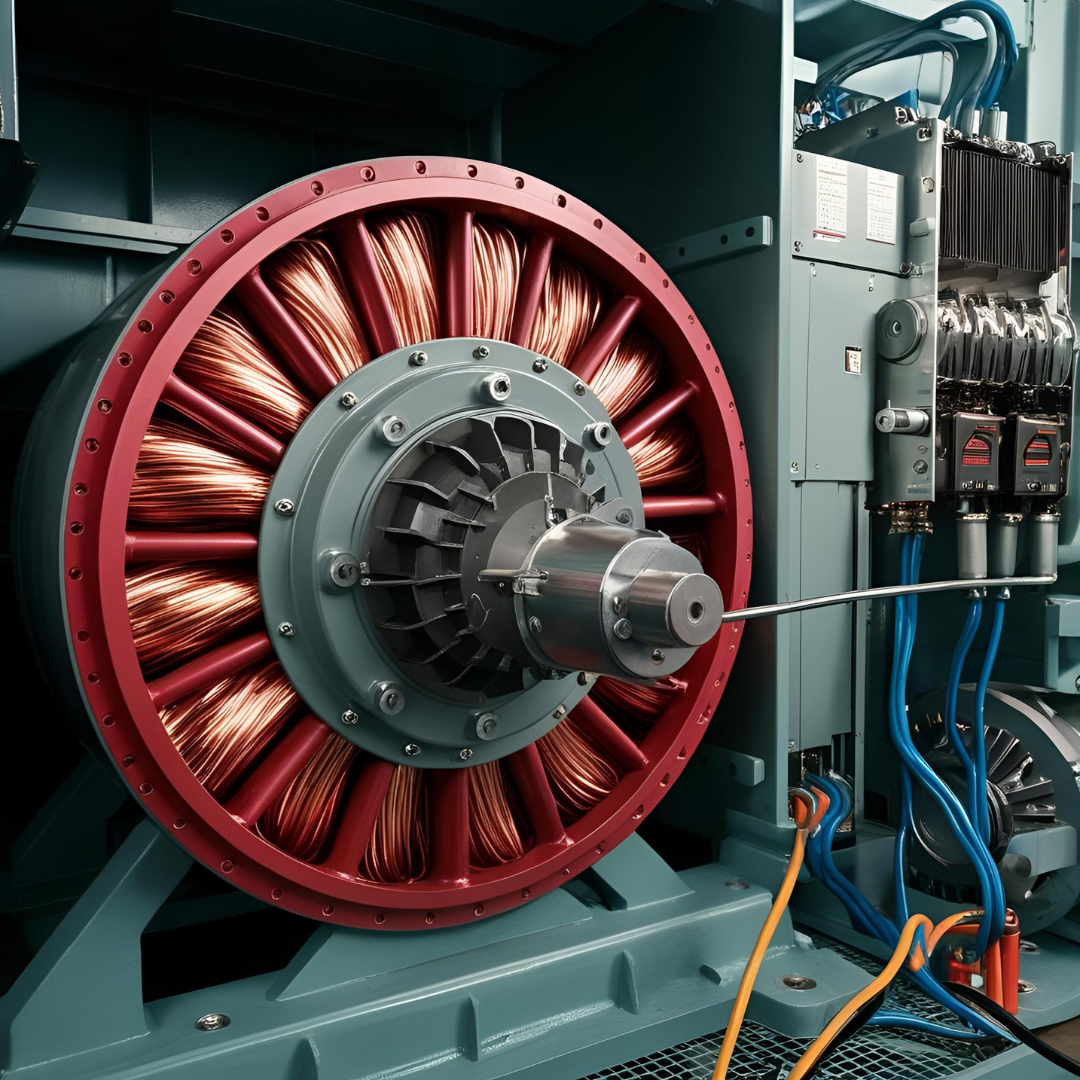

The Heart of Electromechanical Systems

Magnets play a pivotal role in the operation of motors and generators, serving as the core components that convert electrical energy into mechanical energy and vice versa. Their properties and configurations significantly impact the efficiency, power, and performance of these devices.

Types of Magnets Used

Permanent Magnets

Permanent magnets are widely used in both motors and generators due to their ability to maintain a consistent magnetic field without the need for an external power source. Common materials for permanent magnets include:

- Neodymium Iron Boron (NdFeB): Known for their powerful magnetic properties, NdFeB magnets are commonly used in high-performance applications such as electric vehicles and wind turbines.

- Samarium Cobalt (SmCo): These magnets offer excellent thermal stability and resistance to demagnetization, making them suitable for aerospace and military applications.

- Alnico: Composed of aluminum, nickel, and cobalt, Alnico magnets are durable and can withstand high temperatures, though they are generally weaker than NdFeB and SmCo magnets.

- Ferrite: Also known as ceramic magnets, ferrites are cost-effective and provide good resistance to corrosion, commonly used in household appliances and automotive applications.

Electromagnets

Electromagnets generate a magnetic field through the flow of electric current in a coil of wire. They are utilized in applications where adjustable magnetic fields are necessary, such as in variable-speed motors and regenerative braking systems. The strength of an electromagnet can be easily controlled by varying the current flow.

Role of Magnets in Motors

Motors leverage the interaction between magnetic fields and electric currents to produce rotational motion. The fundamental types of motors include:

DC Motors

In direct current (DC) motors, permanent magnets are often used to create a constant magnetic field. The interaction between this field and the current-carrying conductors within the motor generates torque, causing the rotor to spin. Brushless DC motors (BLDC) utilize permanent magnets on the rotor and offer higher efficiency and reliability compared to brushed motors.

AC Motors

Alternating current (AC) motors, such as induction motors and synchronous motors, utilize electromagnets to produce a rotating magnetic field. In synchronous motors, permanent magnets on the rotor interact with the rotating magnetic field generated by the stator, ensuring synchronized rotation. In contrast, induction motors rely on electromagnetic induction to induce current within the rotor, creating motion.

Stepper Motors

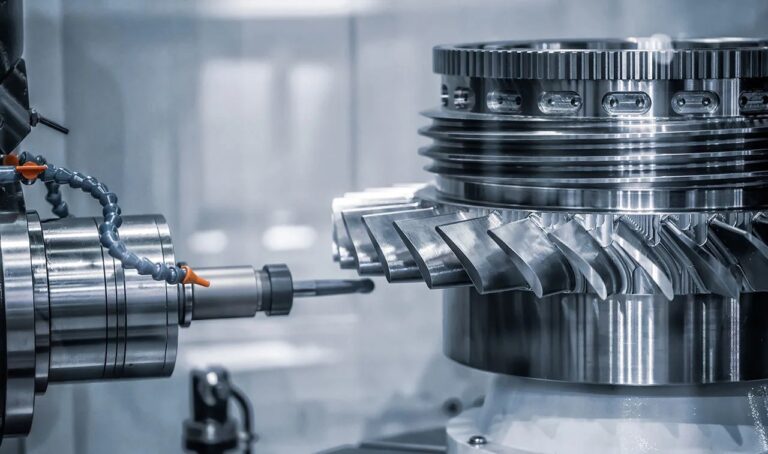

Stepper motors use permanent magnets in combination with electromagnets to achieve precise control of rotational position. These motors are commonly employed in applications requiring accurate positioning, such as 3D printers and CNC machines.

Role of Magnets in Generators

Generators convert mechanical energy into electrical energy through electromagnetic induction. The primary types of generators include:

AC Generators

In AC generators, a rotating magnetic field is produced by either permanent magnets or electromagnets. As the rotor spins, it induces an alternating current in the stator windings. Synchronous generators often use permanent magnets on the rotor, while induction generators employ electromagnetic induction to generate electricity.

DC Generators

DC generators utilize a commutator to produce direct current. Permanent magnets or electromagnets generate a magnetic field, and as the armature rotates within this field, it induces an electromotive force (EMF). The commutator converts the alternating current induced in the armature windings into a unidirectional current.

Renewable Energy Applications

In renewable energy systems such as wind turbines and hydroelectric generators, magnets play a critical role in the conversion of natural energy sources into electrical power. Permanent magnet synchronous generators (PMSG) are favored in these applications for their high efficiency and reliability.

Magnet Configurations and Efficiency

The arrangement and design of magnets within motors and generators greatly influence their efficiency and performance. Key factors include:

Magnetic Circuit Design

The magnetic circuit, comprising the path through which magnetic flux flows, must be carefully designed to minimize losses and maximize efficiency. High-quality magnetic materials and precise geometric configurations are essential to achieving optimal performance.

Cooling and Thermal Management

Efficient cooling systems are crucial in maintaining the performance and longevity of magnets, especially in high-power applications. Overheating can lead to demagnetization and reduced efficiency. Advanced cooling techniques, such as liquid cooling and heat sinks, are employed to manage thermal effects.

Advanced Materials

Ongoing research in magnetic materials aims to develop new alloys and composites with superior magnetic properties and thermal stability. Innovations in nanomaterials and rare-earth elements hold promise for enhancing the performance of magnets in future motors and generators.

Challenges and Future Prospects

Despite their crucial role, magnets in motors and generators face several challenges. The reliance on rare-earth elements in high-performance magnets raises concerns about supply chain stability and environmental impact. Efforts are underway to develop sustainable alternatives and recycling methods to mitigate these issues.

Research and Development

Continued research in magnetic materials, advanced manufacturing techniques, and innovative motor and generator designs is essential to overcoming existing limitations. Collaborative efforts between industry and academia are driving progress toward more efficient, sustainable, and cost-effective solutions.

Emerging Technologies

Emerging technologies, such as magnetic levitation and superconducting magnets, hold the potential to revolutionize the field of electromechanical systems. These advancements promise significant improvements in efficiency, power density, and operational capabilities.

In conclusion, magnets are the heart of motors and generators, enabling the efficient conversion of energy that powers modern society. As technology evolves, the development of advanced magnetic materials and innovative designs will continue to shape the future of these critical devices.