In the ever-evolving world of manufacturing, the demand for high-performance and reliable components continues to rise. One critical element that plays a vital role in many industrial applications is magnets. Samarium cobalt (SmCo) magnets, also known as rare earth magnets, have emerged as a game-changer in the manufacturing sector due to their exceptional properties and versatility. In this blog post, we’ll explore the advantages of SmCo magnets and how they can benefit B2B manufacturing businesses across various industries.

High Magnetic Strength and Stability of SmCo Magnets

One of the most significant advantages of SmCo magnets is their remarkable magnetic strength and stability. These magnets possess a high maximum energy product (BHmax), which translates to a powerful and consistent magnetic field. This characteristic makes SmCo magnets an ideal choice for applications that require precise magnetic force, such as electric motors, generators, and actuators.

Unlike traditional ferrite magnets, SmCo magnets maintain their magnetic properties even at elevated temperatures, making them suitable for use in harsh environments. This thermal stability ensures consistent performance and reliable operation in manufacturing processes that involve high-temperature exposure.

Resistance to Corrosion and Demagnetization

SmCo magnets are highly resistant to corrosion and demagnetization, making them suitable for use in demanding industrial environments. Their corrosion resistance allows them to withstand exposure to harsh chemicals, moisture, and other environmental factors, reducing the risk of degradation and extending their service life.

Additionally, SmCo magnets exhibit superior resistance to demagnetization, meaning they can maintain their magnetic properties even in the presence of opposing magnetic fields or external forces. This feature is particularly beneficial in applications where magnets are subjected to high mechanical stress or vibration, such as in industrial machinery and equipment.

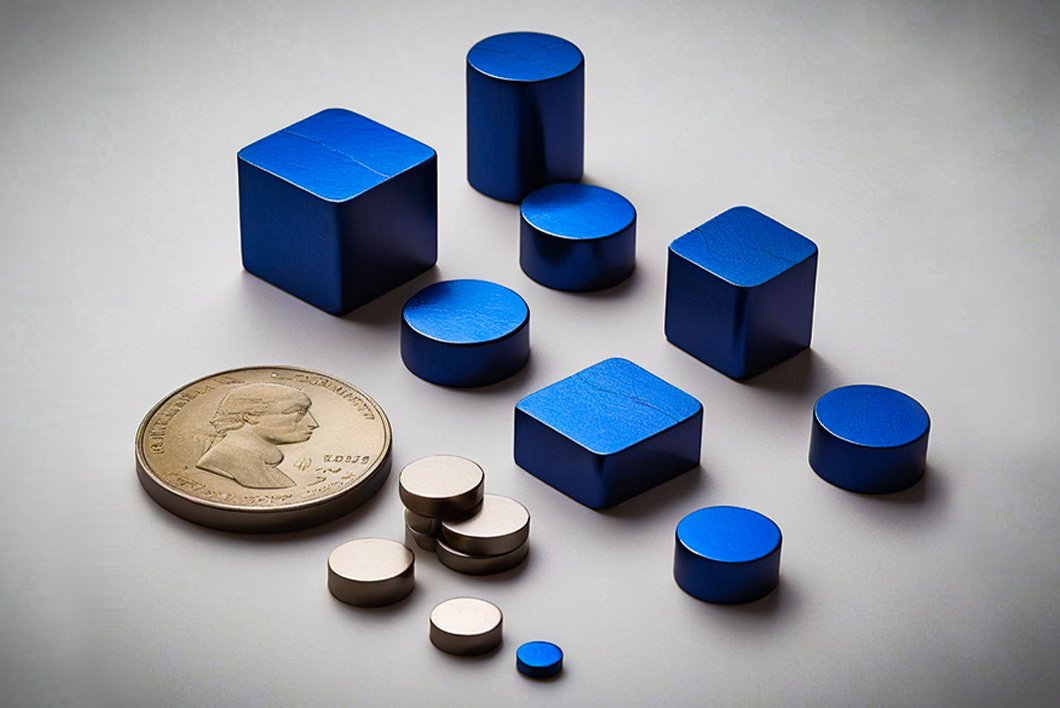

Compact Size and Weight

Despite their impressive magnetic properties, SmCo magnets offer a significant advantage in terms of size and weight. These magnets can generate high magnetic fields while maintaining a compact form factor, allowing manufacturers to design and produce smaller, lighter, and more efficient components.

The compact size and lightweight nature of SmCo magnets make them ideal for applications where space and weight are critical considerations, such as in aerospace, automotive, and robotics industries. By utilizing these magnets, manufacturers can optimize product design, reduce material costs, and improve overall efficiency.

Versatility and Customization

SmCo magnets are highly versatile and can be customized to meet specific application requirements. These magnets can be produced in various shapes, sizes, and grades, allowing manufacturers to tailor their magnetic properties to fit specific performance needs.

Furthermore, SmCo magnets can be coated with various materials, such as nickel, gold, or epoxy, to enhance their durability, corrosion resistance, or surface properties. This versatility enables manufacturers to adapt SmCo magnets to their unique production processes and environmental conditions, ensuring optimal performance and reliability.

Energy Efficiency and Sustainability

In an era where energy efficiency and sustainability are becoming increasingly important,

offer a compelling solution for reducing energy consumption and environmental impact. Their high magnetic strength and stability allow manufacturers to design and produce more efficient electric motors, generators, and other electromechanical devices.

By utilizing it , manufacturers can create products that consume less energy while delivering the same or better performance. This not only reduces operational costs but also contributes to a more sustainable manufacturing process, aligning with environmental regulations and consumer demand for eco-friendly products.

Conclusion

Samarium cobalt magnets have emerged as a game-changer in the manufacturing sector, offering numerous advantages that can benefit B2B businesses across various industries. From their exceptional magnetic strength and thermal stability to their resistance to corrosion and demagnetization, It provide a reliable and durable solution for a wide range of applications.

Additionally, their compact size, lightweight, and versatility make them ideal for optimizing product design, reducing material costs, and improving overall efficiency. By embracing the advantages of it manufacturers can stay ahead of the curve, meet the demands of a rapidly evolving market, and contribute to a more sustainable future.