In the fast-paced world of automotive manufacturing, efficiency, accuracy, and innovation have become more important than ever. As vehicles evolve with new technologies, the demand for precision-crafted components is rising. This is where custom machining steps in. For Magworks LLC, this approach has transformed the way parts are made. With machining automotive parts now a cornerstone of the industry, manufacturers are embracing customized solutions to stay ahead.

The Precision Edge of Custom Machining

When it comes to automotive production, the smallest error can lead to significant consequences. Custom machining allows manufacturers to produce parts that meet exact specifications. This method ensures every piece is flawless and fits perfectly into larger assemblies.

Unlike mass production, where parts are made in bulk, custom machining focuses on accuracy over quantity. This is especially important for critical automotive components like engine parts, brake systems, and transmission gears. With custom machining, every detail matters, providing a level of precision that mass production methods simply can’t match.

Meeting Complex Requirements with Ease

Today’s vehicles aren’t just machines on wheels. They are equipped with advanced technologies like sensors, automated controls, and electric drive systems. These features require specialized components. Custom machining allows manufacturers to design parts tailored to these specific needs. For example, lightweight yet durable parts can be machined for electric vehicles to enhance performance without sacrificing strength.

Moreover, this approach supports the creation of prototypes, making it easier for companies to test new designs before launching full production. By partnering with reputed companies, manufacturers gain access to flexible solutions that cater to complex automotive needs without compromising quality.

The Materials That Shape the Future

The choice of material is just as critical as the machining process itself. Custom machining accommodates a variety of materials, from traditional metals like steel and aluminum to composites and even some advanced polymers. These materials are selected based on the demands of the specific part—whether it’s high heat resistance, reduced weight, or enhanced durability.

For instance, steel and titanium might be used in engine components to withstand extreme temperatures, while aluminum is often chosen for its lightweight properties in electric and hybrid vehicle parts. Custom machining ensures these materials are shaped with unparalleled precision, resulting in parts that meet the highest standards.

Saving Time and Reducing Costs

While custom machining might seem like an expensive option upfront, it often saves money in the long run. The process reduces waste by crafting parts to precise measurements, eliminating excess material use. Additionally, the reliability of machined parts reduces the need for frequent repairs or replacements, providing cost savings over time.

Custom machining also streamlines production timelines. Instead of relying on pre-made parts that may not fit perfectly, manufacturers can order tailored components and integrate them directly into their processes. Magworks LLC perfected this approach, delivering efficiency alongside quality.

Advanced Technology Powering Custom Machining

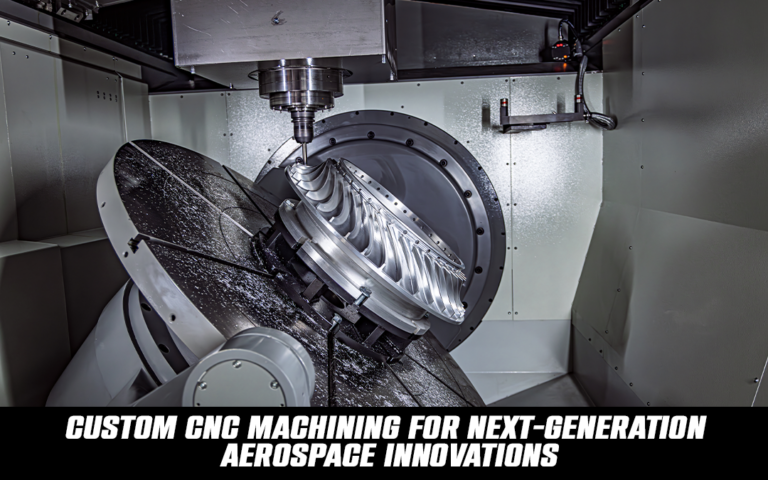

Modern custom machining relies heavily on advanced technologies. CNC (Computer Numerical Control) machines play a significant role in this process. These machines use computer-controlled tools to cut, drill, and shape materials into precise forms. This technology eliminates human error, ensuring consistent quality across multiple parts.

Additionally, innovations like 3D modeling and simulation have revolutionized the design process. Before machining even begins, digital prototypes allow manufacturers to visualize parts in detail. Adjustments can be made instantly, saving time and resources during the actual production phase.

Sustainability in Custom Machining

Sustainability is an increasingly important consideration in the automotive industry. Custom machining supports greener manufacturing practices by minimizing waste and enabling the use of eco-friendly materials. Instead of producing surplus parts, this approach focuses only on what is needed, reducing environmental impact.

At Magworks LLC, sustainable practices are integrated into every step of the machining process. By prioritizing efficiency and using recyclable materials where possible, they contribute to a more sustainable future for automotive production.

Custom Machining Beyond Automotive

While custom machining has become a staple in automotive parts manufacturing, its applications go beyond this industry. Fields like aerospace, medical devices, and even defense heavily rely on precision machining to meet their strict requirements.

For example, in the defense sector, machining parts with extreme accuracy can make a critical difference in performance and safety. Magworks LLC specializes not only in machining automotive parts but also offers expertise in defense machining, highlighting their ability to adapt their processes for various industries.

End Summary: A Bright Future for Custom Machining!

As the automotive industry continues to evolve, so will the need for high-precision manufacturing techniques. Custom machining stands out as a reliable solution, offering unmatched accuracy, adaptability, and efficiency. Magworks LLC demonstrates how this technology can push the boundaries of what’s possible.

Whether crafting components for traditional vehicles or electric cars, machining automotive parts ensures the final product meets the highest standards. And with its versatility extending to fields like defense machining, it’s clear this technology is here to stay.

For automotive manufacturers looking to stay competitive, investing in custom machining isn’t just an option—it’s a necessity!